Suction and Floating Integrated Table

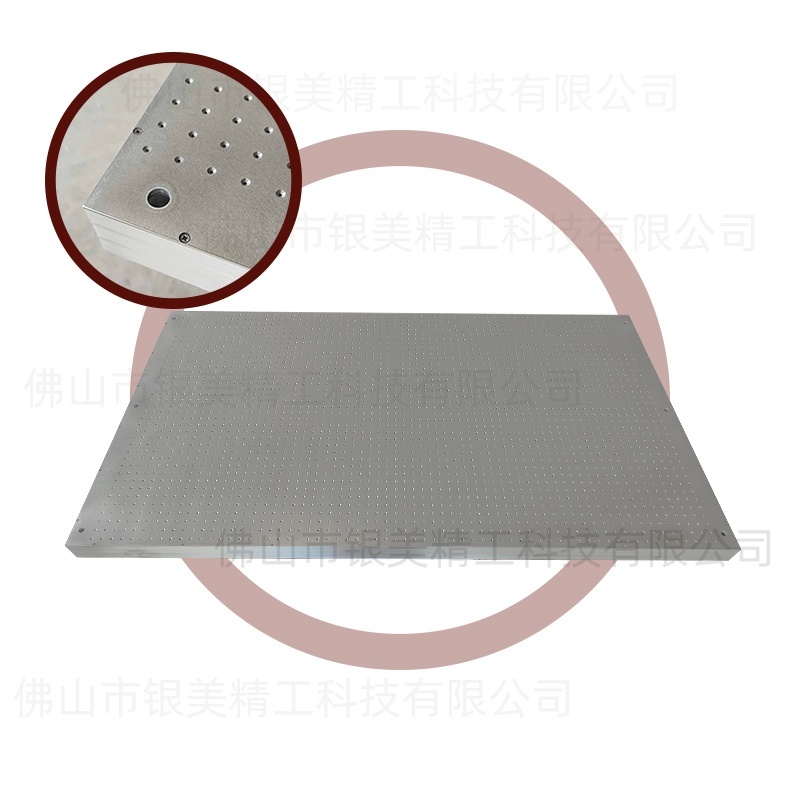

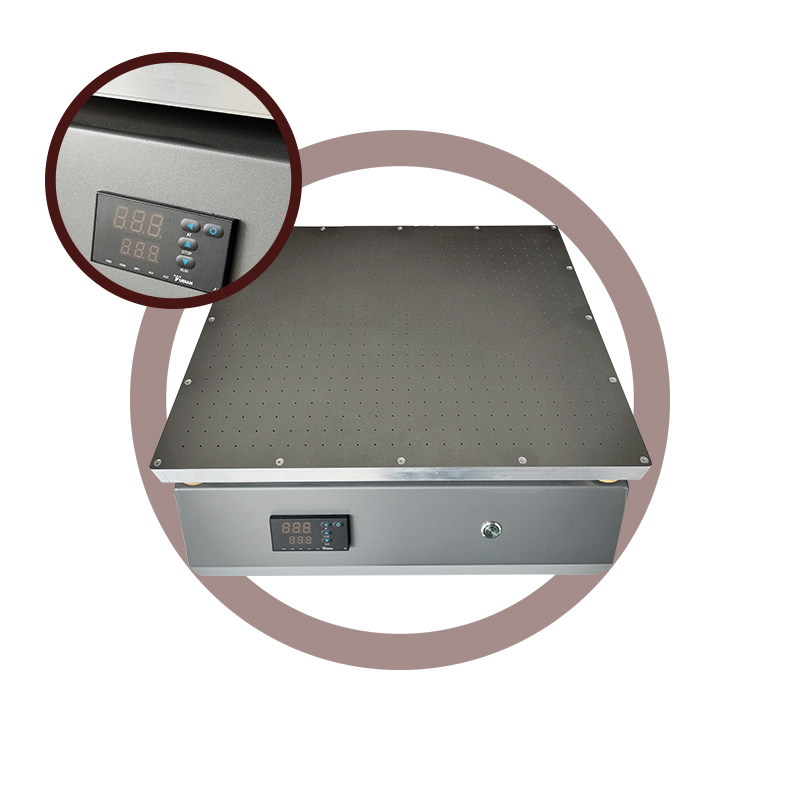

Integrated suction and floating platform YM-1300*800*42.5, dual-use for adsorption and air flotation, freely switchable, easy to operate

key word:

Air flotation series platform

Classification:

Product details

Parameters of the integrated suction floating platform YM-1300*800*42.5 are as follows:

Platform specifications: 1300*800*42.5

Platform thickness: 42.5

Panel material: Aluminum alloy

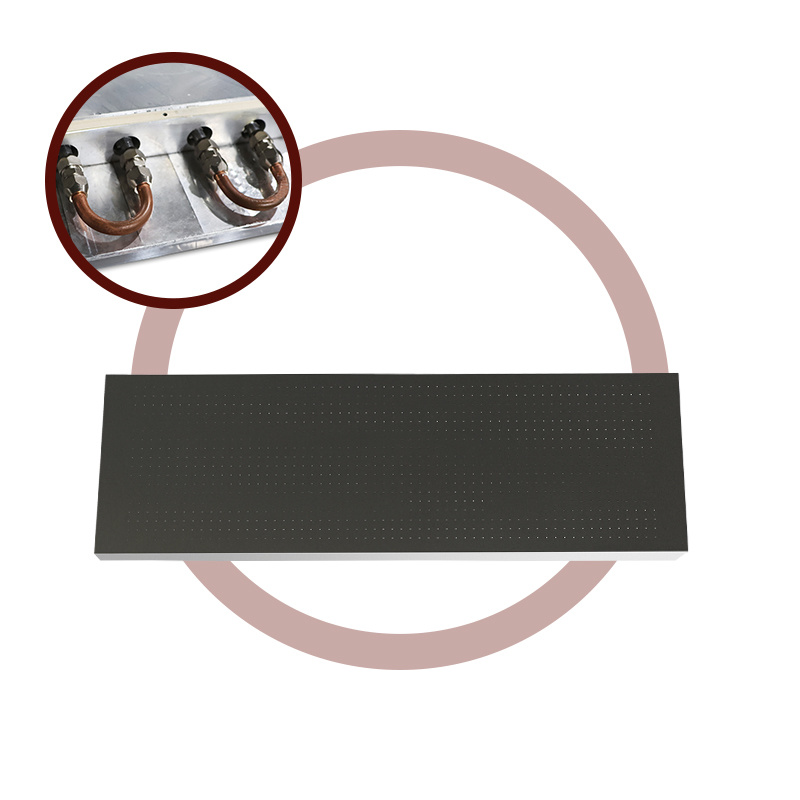

Interface type: Flange

Surface treatment: Hard anodizing

Flatness: 0.20mm

Panel and bottom plate thickness: 2.0mm

Suction port diameter: 50 (bottom opening)

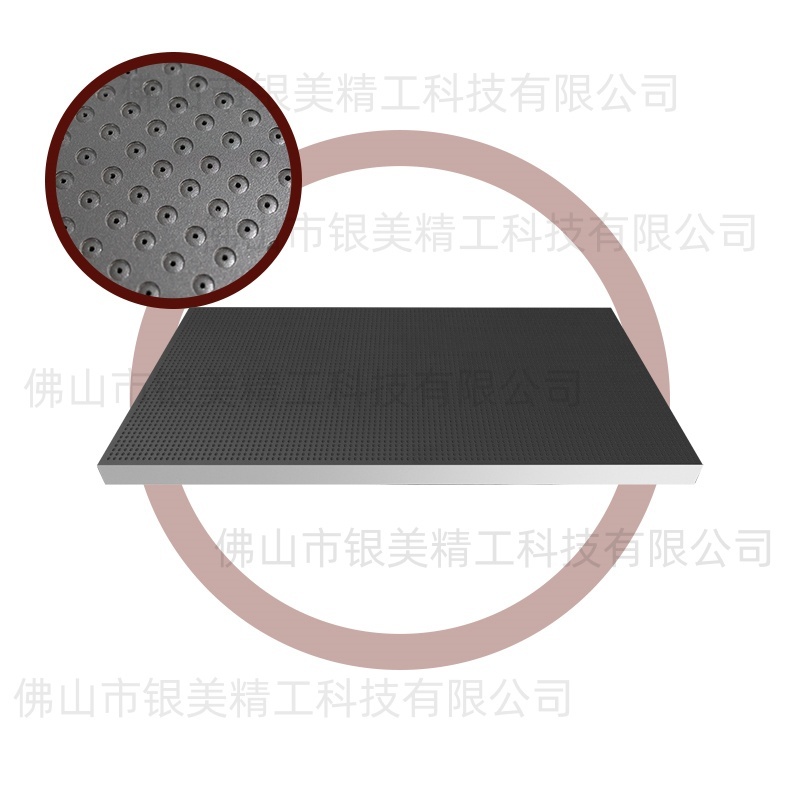

Floating bead pitch: 100*100mm

Floating bead diameter: ∅9mm

Floating bead protrusion from table surface: 1.5mm

Features of Yinmei Precision Vacuum Suction Platform:

The Yinmei Precision Vacuum Suction Platform has an aluminum honeycomb structure, made of aluminum alloy material, with a highly flat surface. Besides the advantages of aluminum honeycomb panels such as light weight, high strength, high rigidity, bending resistance, and flexural resistance, this platform also features high flatness, low deflection, strong suction force, and scratch and wear resistance. Detailed advantages are as follows:

1. Large surface area with high flatness

The surface size of the Yinmei Precision Vacuum Suction Platform can reach 2100*3950mm (larger sizes can be spliced). It has excellent flatness and deflection, with flatness generally controlled within 0.02mm, and as low as 0.01mm; deflection under a 30kg load is less than 0.01mm.

2. Lightweight with high load capacity

The Yinmei Precision Vacuum Suction Platform uses high-quality aluminum honeycomb structure, entirely made of aluminum alloy materials, with a density of about 20-30kg per square meter. It can bear 30kg without deformation.

3. Strong and uniform suction

The Yinmei Precision Vacuum Suction Platform is optimally designed to ensure that all platform performance is maintained while providing strong and uniform suction at any position on the platform.

4. Scratch and wear resistant

The surface of the Yinmei Precision Vacuum Suction Platform can be treated with various processes including fluorocarbon PVDF powder coating, anodizing, and hard anodizing. Among these, hard anodizing offers the best scratch and wear resistance, with surface hardness reaching HV500-700.

5. Customizable

The Yinmei Precision Vacuum Suction Platform can be custom-made according to customer requirements, including platform size, hole diameter and spacing, suction area, suction port diameter, number of suction ports, interface type, and any zoning for individual suction or no suction.

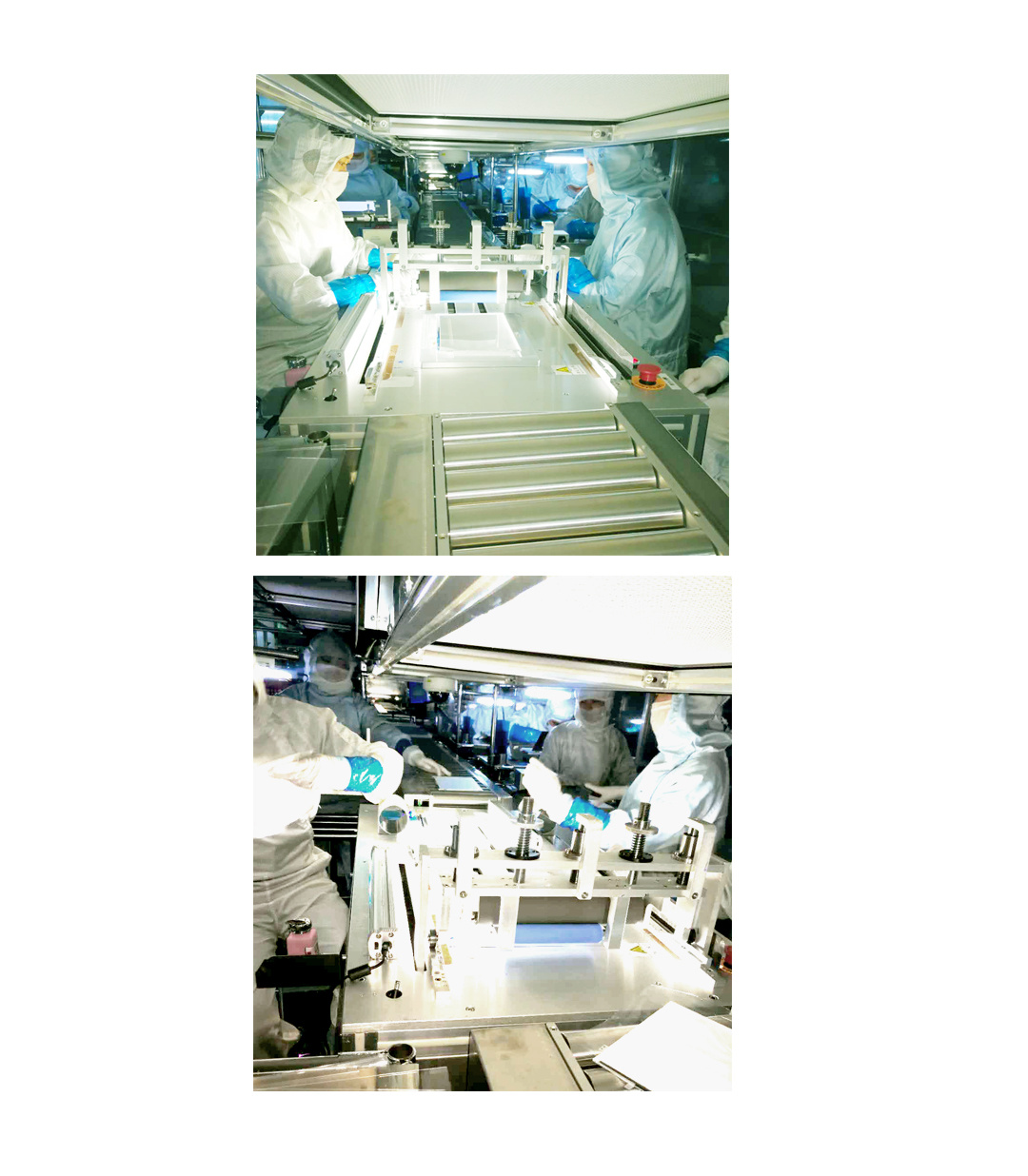

Application cases: (glass processing equipment, automation equipment, etc.)

Prev

Next

Prev

Next

Related products