Small-Scale screen separating machine

key word:

Classification:

Product details

Technical Parameters And Characteristics

|

SPEC |

THICKNESS |

PANEL HOLE DIAMETER |

PANEL HOLE SPACING |

PANEL MATERIAL |

INTERFACE MODE |

|

2500*1300*42.5 |

42.5 |

0.8 |

20 |

Aluminum alloy |

flange |

|

SURFACE FINISHING |

FLATNESS (MM) |

PANEL THICKNESS |

BACK THICKNESS |

PUMPING APERTURE |

|

|

Hard oxidation |

≦0.10 |

2.0 |

2.0 |

Φ50 |

|

Above Technical Specifications Can Be Customized Basing On The Following Date

|

SPEC |

THICKNESS |

PANEL HOLE DIAMETER |

PANEL HOLE SPACING |

PARTITION |

INTERFACE MODE |

|

Customized |

25 |

0.8 |

10 |

|

flange |

|

|

35.5 |

1.0 |

20 |

Customized |

Screw |

|

|

42.5 |

1.5 |

30 |

|

|

|

MAX:4000*2100 |

53.5 |

Customized |

|

|

|

|

|

75 |

|

|

|

|

|

SURFACE FINISHING |

FLATNESS (MM) |

PANEL THICKNESS |

BACK THICKNESS |

PUMPING APERTURE |

|

|

Hard oxidation |

≦0.10 |

2.0 |

2.0 |

Φ40 |

|

|

Aluminium primary |

|

|

3.0 |

Φ50 |

|

|

PVDF |

|

|

2.0 |

Customized |

|

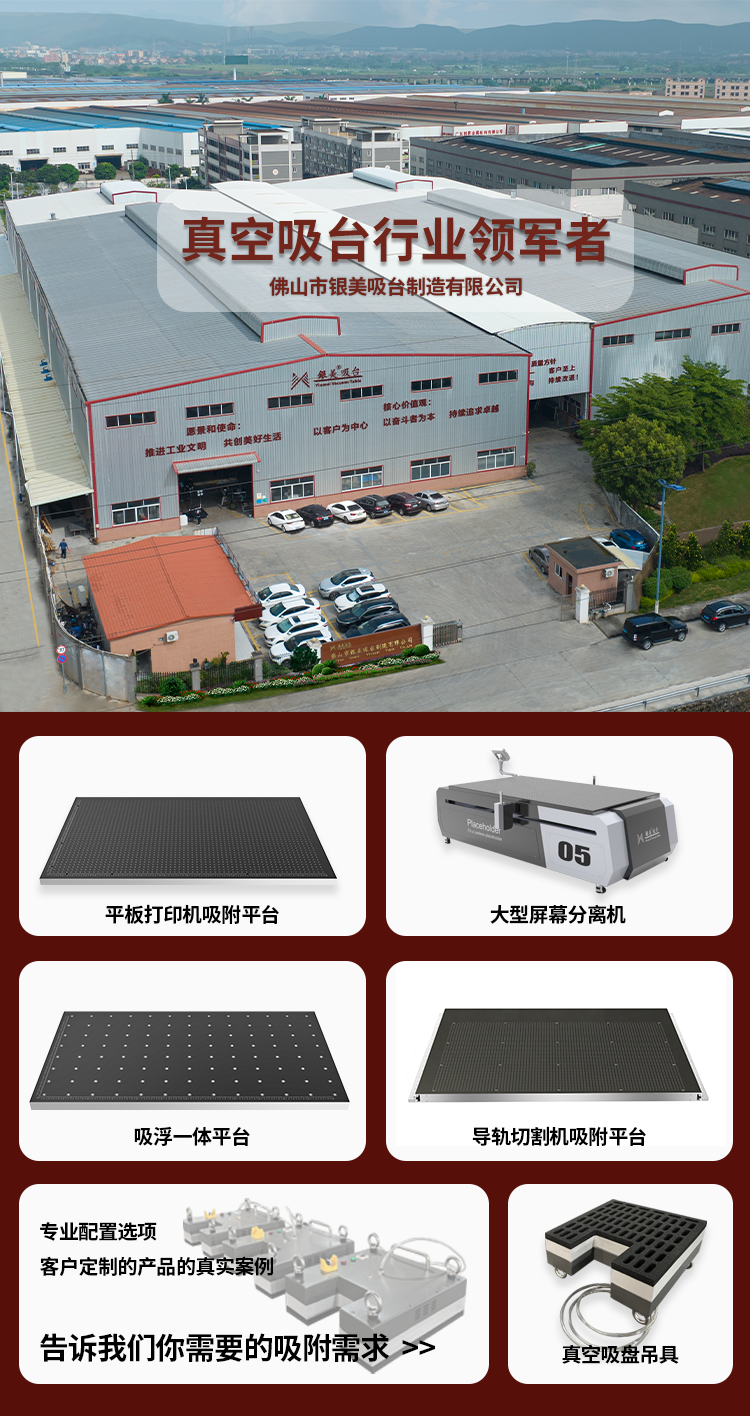

Small-Scale Screen Separator Machine

This compact screen separator is a specialized machine for repairing smartphones, tablets, and other electronic devices. It is designed to efficiently separate the screen from the glass cover or touch layer with precision and ease.

Advantages

Compact and portable: Lightweight design for easy handling and workspace flexibility.

Consistent suction and sturdy build: Ensures stable screen hold-down during separation.

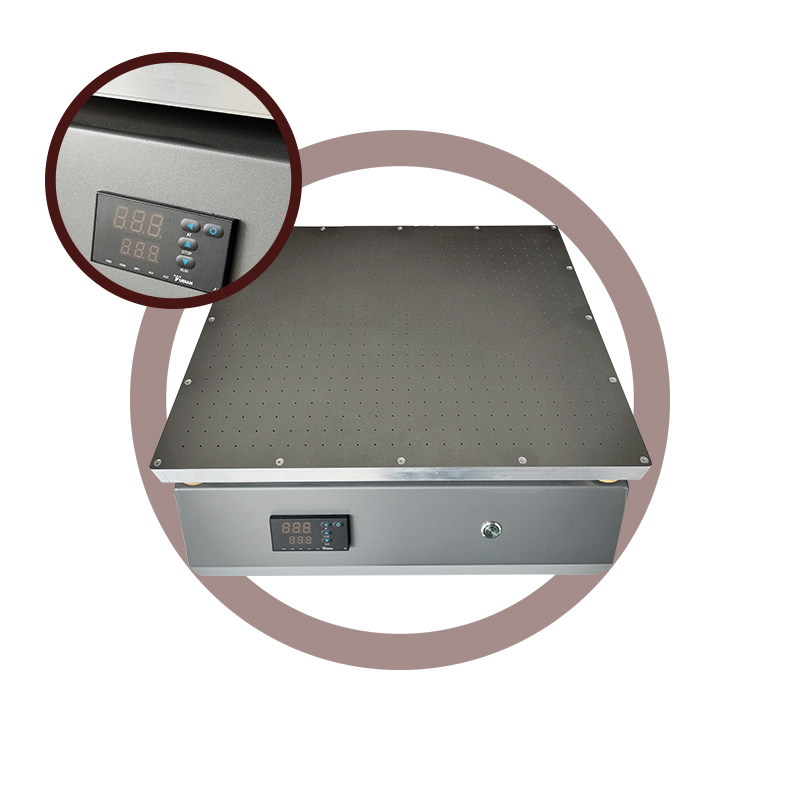

Precise temperature control: Enables fast and safe screen removal without damage.

Desktop-grade model for laboratory use

Compact structure with smart touch control for quick and intuitive start/stop operation.

Industrial-grade safety system

Equipped with dual-layer electrical protection, including overload and grounding safety mechanisms.

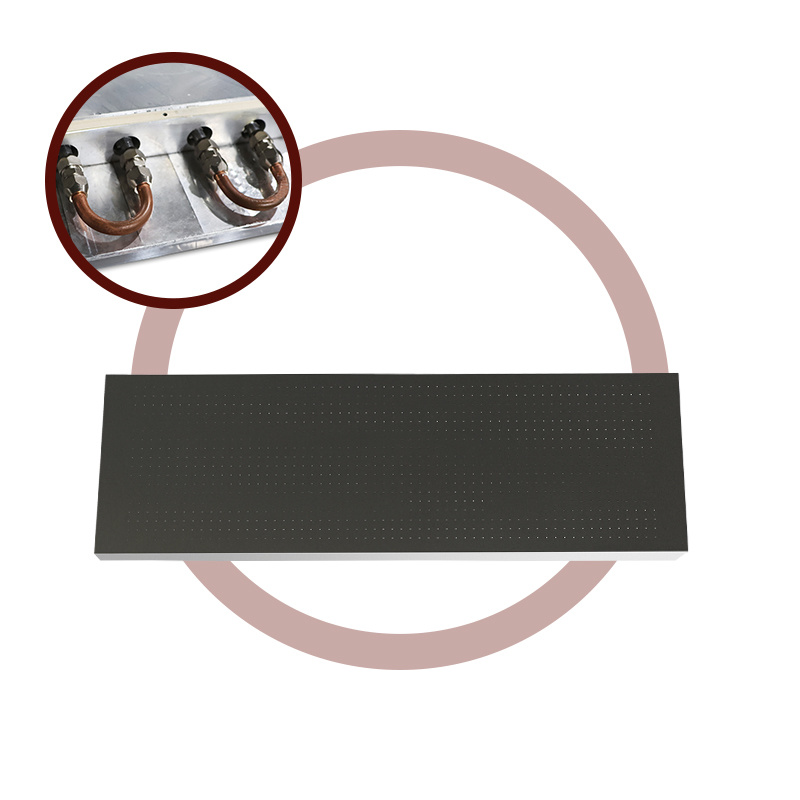

Dual-function heated vacuum table

Integrated heating and vacuum modes work in sync to eliminate material shifting during separation.

Wide-range temperature control up to 150°c (+0.5°C)

Features intelligent thermal regulation with both LED digital display and manual control interface.

Characteristics Of YIMIWELL Vacuum Table:

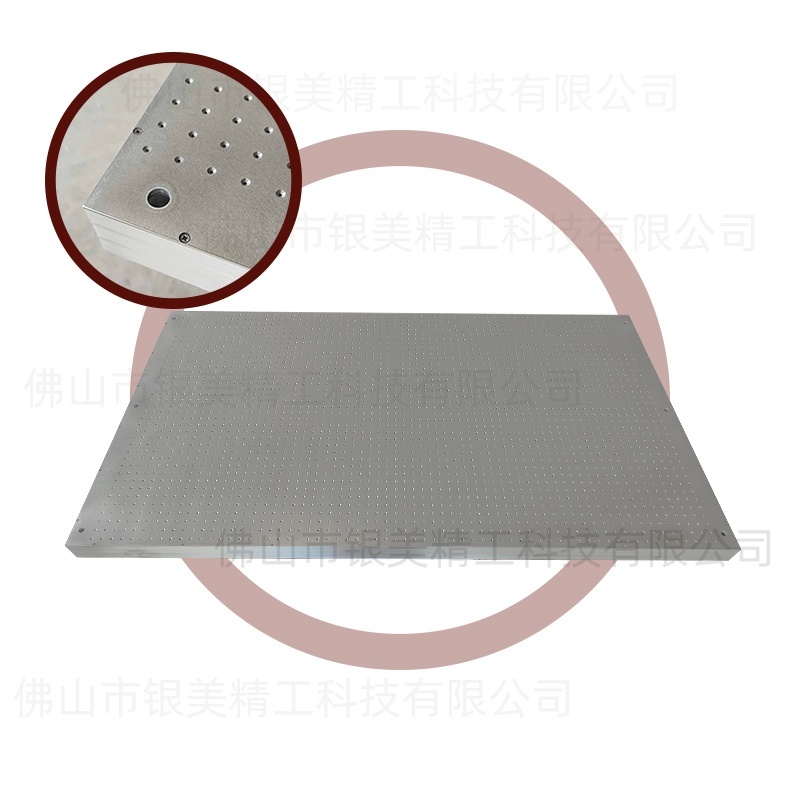

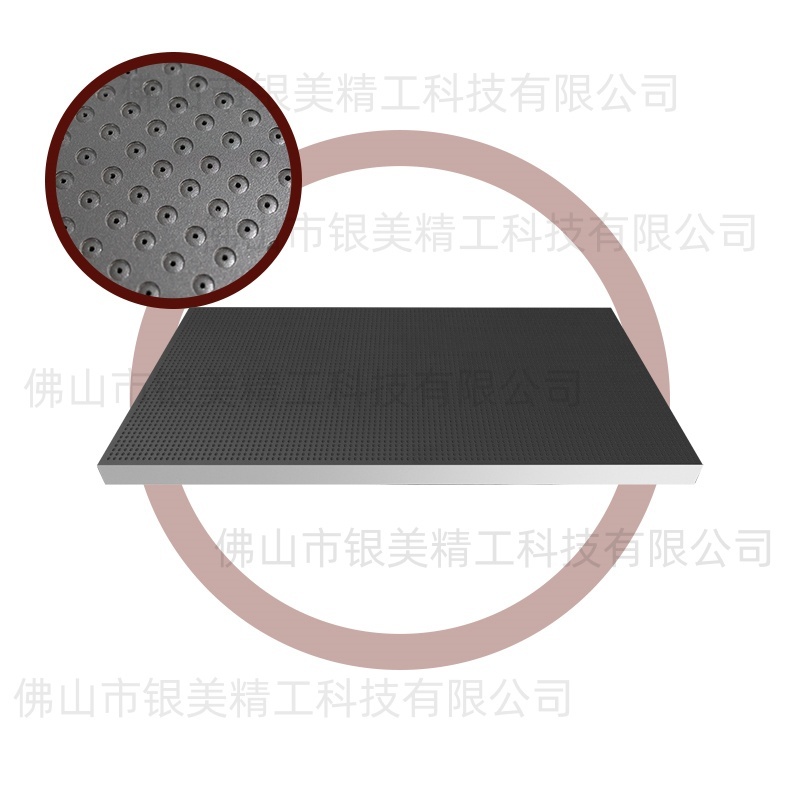

Yimiwell Vacuum Table are made of aluminum alloy in honeycomb structure, with extremely high flatness of surface. In addition to the advantages of light weight, high strength, high rigidity, bending resistance and deflection resistance, this platform also has the advantages of high flatness, small deflection value, large adsorption force, scratch resistance and wear resistance.

THE DETAILED ADVANTAGES ARE AS FOLLOWS:

LARGE SURFACE WITH HIGH FLATNESS

The maximum length and width dimensions of the Yimiwell vacuum table panel can reach 4000×2100mm (splicing is available for sizes exceeding this range). It boasts excellent flatness and deflection performance:

- Flatness: Generally controlled within 0.20mm, with the minimum down to 5μm.

- Deflection: Less than 0.10mm under a load of 30 kg.

LIGHT WEIGHT AND LARGE BEARING CAPACITY

Yimiwell vacuum table uses aviation-grade aluminum honeycomb structure with all-aluminum alloy integrated molding. Lightweight design ensures >60kg/m² single-point load-bearing without deformation, combining high strength and stability.

GREAT SUCTION IN WELL-DISTRIBUTED

Yimiwell vacuum table ensures the performance of the platform are not affected and also makes the suction force great in well-distributed at any position.

ANTI-SCRATCH AND WEAR-RESISTANT

The surface of Yimiwell vacuum table can undergo natural anodizing and hard anodizing treatments. Among them, hard anodizing provides the best scratch and wear resistance, with a maximum surface hardness of up to Hv500.

YIMIWELL VACUUM TABLE CAN BE CUSTOMIZED BASING ON CUSTOMER'S DEMAND.

Related products