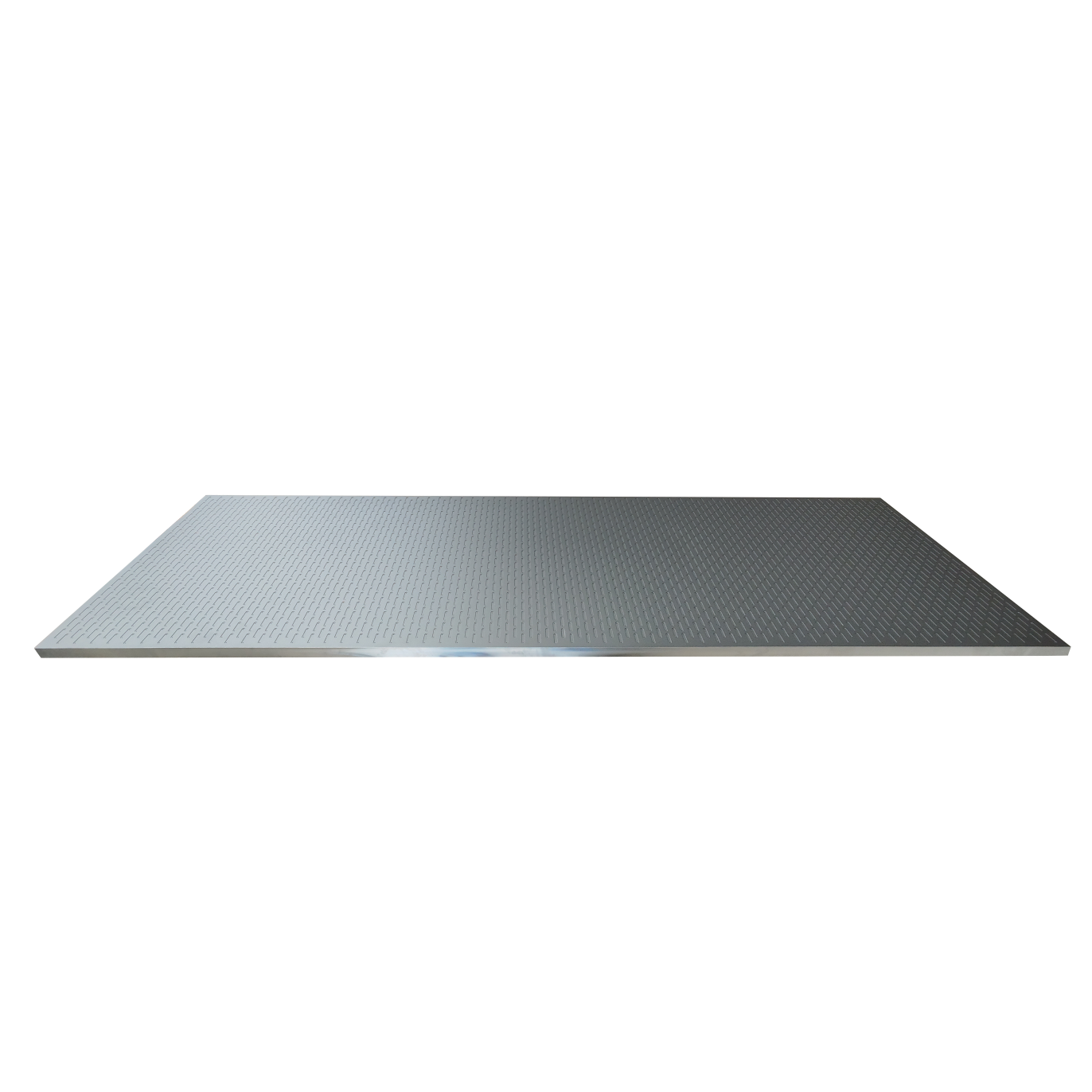

Corrugated Paper Belt Printer Vacuum Table

key word:

Classification:

Product details

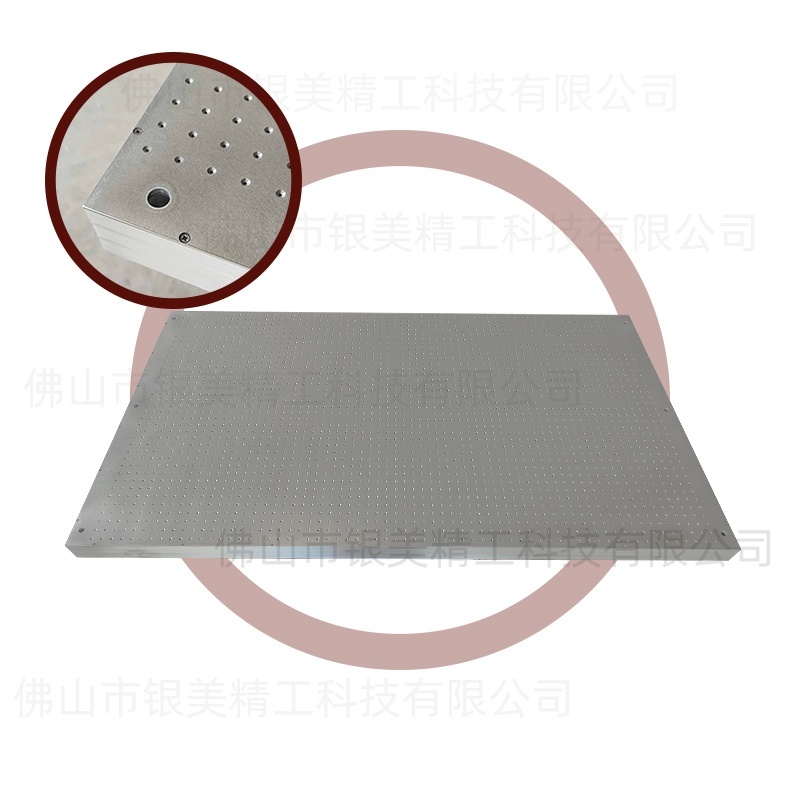

Vacuum hold-down system for ensuring stable material positioning in flatbed printing applications

Flatness precision: 0.10mm

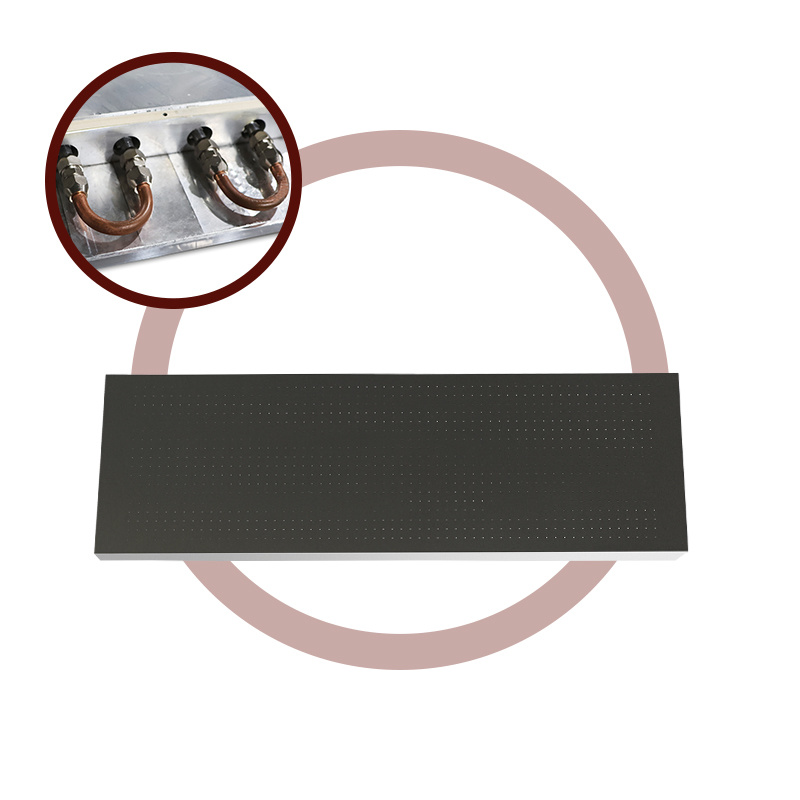

Optimized performance: Engineered for powerful and even suction across the entire vacuum table without compromising performance, enhancing print stability and accuracy.

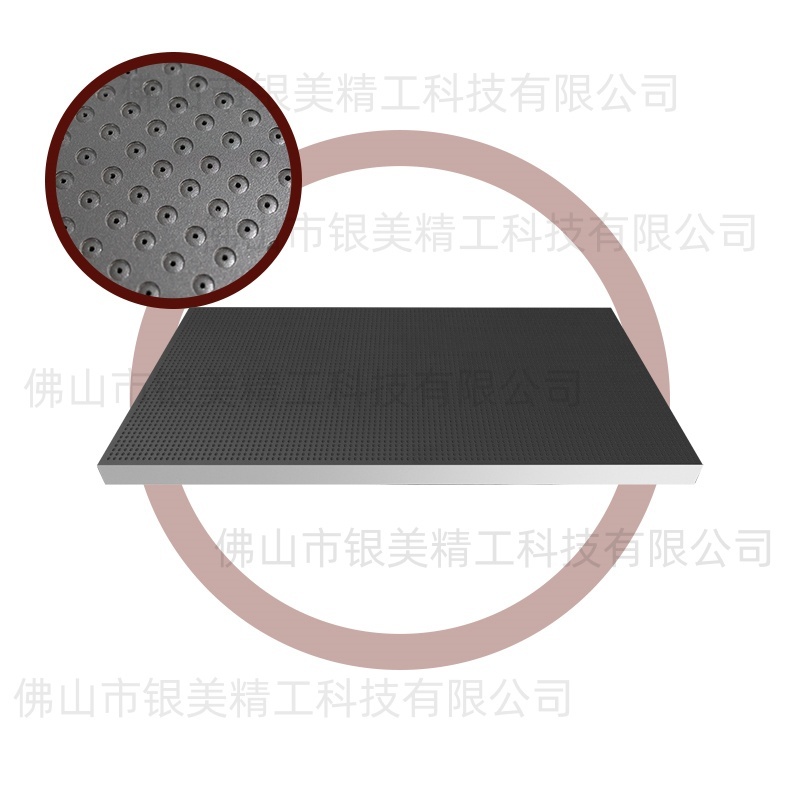

Lightweight yet high load capacity: Constructed with high-quality aluminum honeycomb core materials. Weighing approximately 25–35 kg/m², it supports up to 30 kg without deformation.

Scratch and wear resistant surface: Available in multiple surface treatments, including powder coating, anodizing, and hard anodizing. Hard anodized surfaces offer superior resistance with surface hardness up to HV350–550, ideal for long-term industrial use. Fully customizable based on your specifications, including size, hole layout, and structural features.

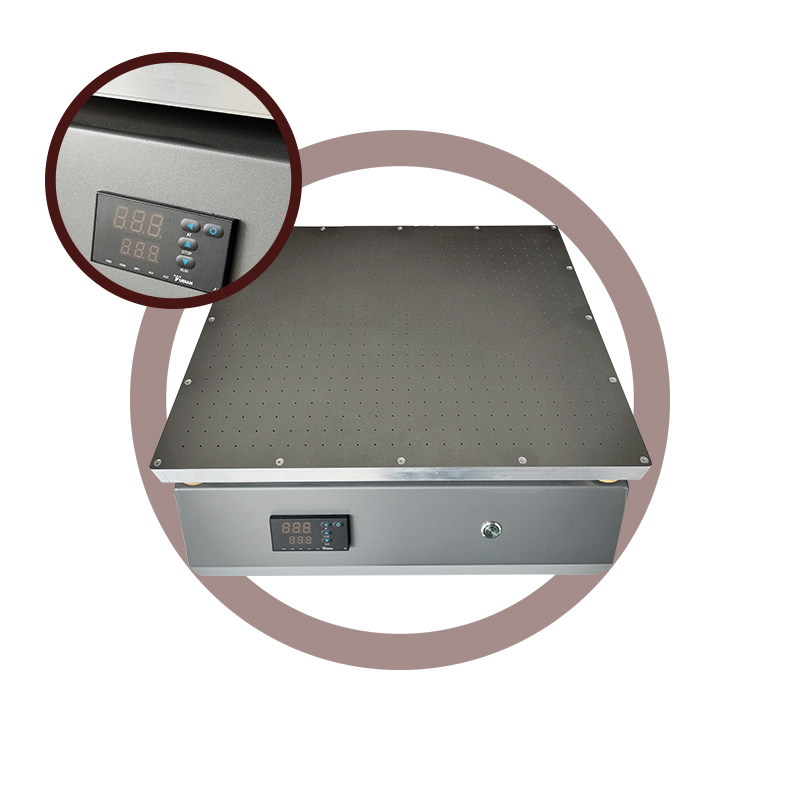

Product Name: Corrugated Paper Printer Vacuum Table

Product Features:

- Flatness ≤ 0.1mm Customizable suction grooves available

- Strong suction power, uniform suction

- Honeycomb structure, lightweight, high strength

Technical Parameters And Characteristics

|

SPEC |

THICKNESS |

PANEL HOLE DIAMETER |

PANEL HOLE SPACING |

PANEL MATERIAL |

INTERFACE MODE |

|

2500*1300*42.5 |

42.5 |

0.8 |

20 |

Aluminum alloy |

flange |

|

SURFACE FINISHING |

FLATNESS (MM) |

PANEL THICKNESS |

BACK THICKNESS |

PUMPING APERTURE |

|

|

Hard oxidation |

≦0.10 |

2.0 |

2.0 |

Φ50 |

|

Above Technical Specifications Can Be Customized Basing On The Following Date

|

SPEC |

THICKNESS |

PANEL HOLE DIAMETER |

PANEL HOLE SPACING |

PARTITION |

INTERFACE MODE |

|

Customized |

25 |

0.8 |

10 |

|

flange |

|

|

35.5 |

1.0 |

20 |

Customized |

Screw |

|

|

42.5 |

1.5 |

30 |

|

|

|

MAX:4000*2100 |

53.5 |

Customized |

|

|

|

|

|

75 |

|

|

|

|

|

SURFACE FINISHING |

FLATNESS (MM) |

PANEL THICKNESS |

BACK THICKNESS |

PUMPING APERTURE |

|

|

Hard oxidation |

≦0.10 |

2.0 |

2.0 |

Φ40 |

|

|

Aluminium primary |

|

|

3.0 |

Φ50 |

|

|

PVDF |

|

|

2.0 |

Customized |

|

|

Surface Treatment |

Flatness mm |

Panel Thickness |

Base Plate Thickness |

Suction Port Diameter |

|

Hard Oxidation |

≤ 0.10 |

2.0 |

2.0 |

Φ 40 |

|

Bright Aluminum |

|

|

3.0 |

Φ 50 |

|

PVDF |

|

|

|

Φ 75 |

|

|

|

|

|

Customizable |

Characteristics Of YIMIWELL Vacuum Table:

Yimiwell Vacuum Table are made of aluminum alloy in honeycomb structure, with extremely high flatness of surface. In addition to the advantages of light weight, high strength, high rigidity, bending resistance and deflection resistance, this platform also has the advantages of high flatness, small deflection value, large adsorption force, scratch resistance and wear resistance.

THE DETAILED ADVANTAGES ARE AS FOLLOWS:

LARGE SURFACE WITH HIGH FLATNESS

The maximum length and width dimensions of the Yimiwell vacuum table panel can reach 4000×2100mm (splicing is available for sizes exceeding this range). It boasts excellent flatness and deflection performance:

- Flatness: Generally controlled within 0.20mm, with the minimum down to 5μm.

- Deflection: Less than 0.10mm under a load of 30 kg.

LIGHT WEIGHT AND LARGE BEARING CAPACITY

Yimiwell vacuum table uses aviation-grade aluminum honeycomb structure with all-aluminum alloy integrated molding. Lightweight design ensures >60kg/m² single-point load-bearing without deformation, combining high strength and stability.

GREAT SUCTION IN WELL-DISTRIBUTED

Yimiwell vacuum table ensures the performance of the platform are not affected and also makes the suction force great in well-distributed at any position.

ANTI-SCRATCH AND WEAR-RESISTANT

The surface of Yimiwell vacuum table can undergo natural anodizing and hard anodizing treatments. Among them, hard anodizing provides the best scratch and wear resistance, with a maximum surface hardness of up to Hv500.

YIMIWELL VACUUM TABLE CAN BE CUSTOMIZED BASING ON CUSTOMER'S DEMAND.

Related products