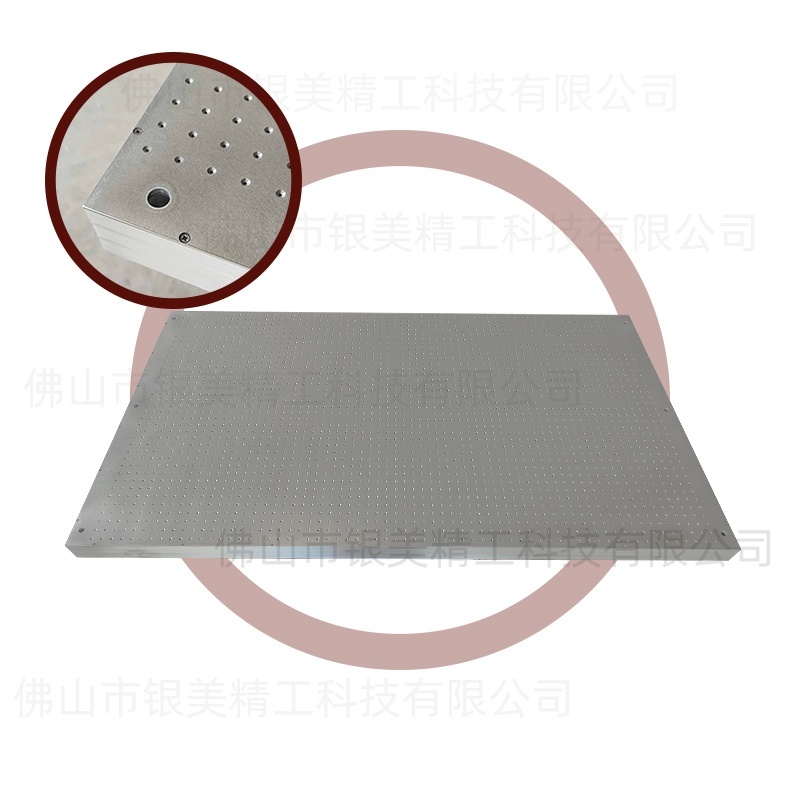

UV Flatbed Printer Vacuum Table (small board)

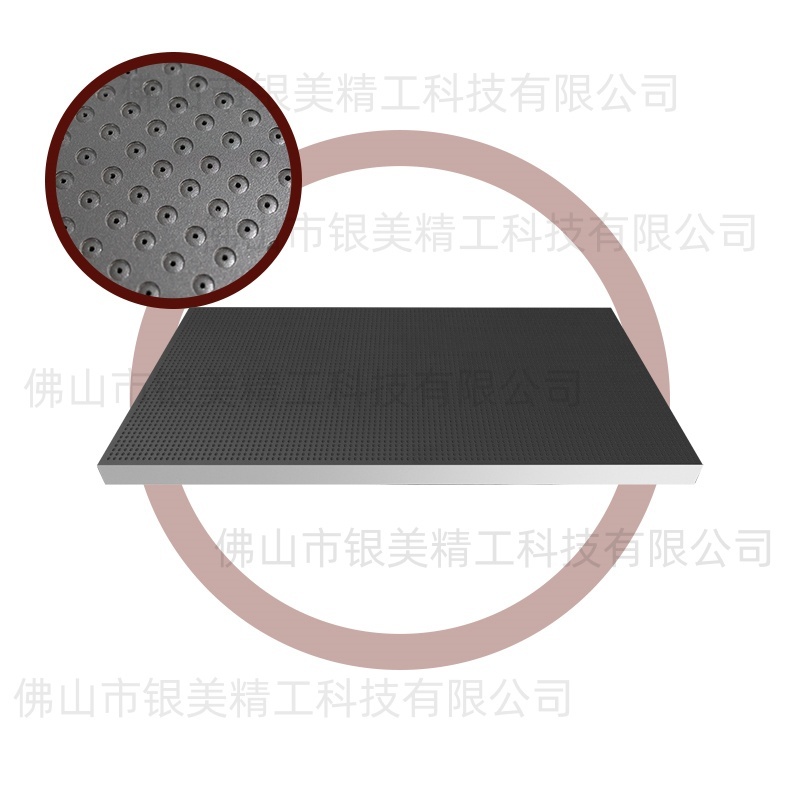

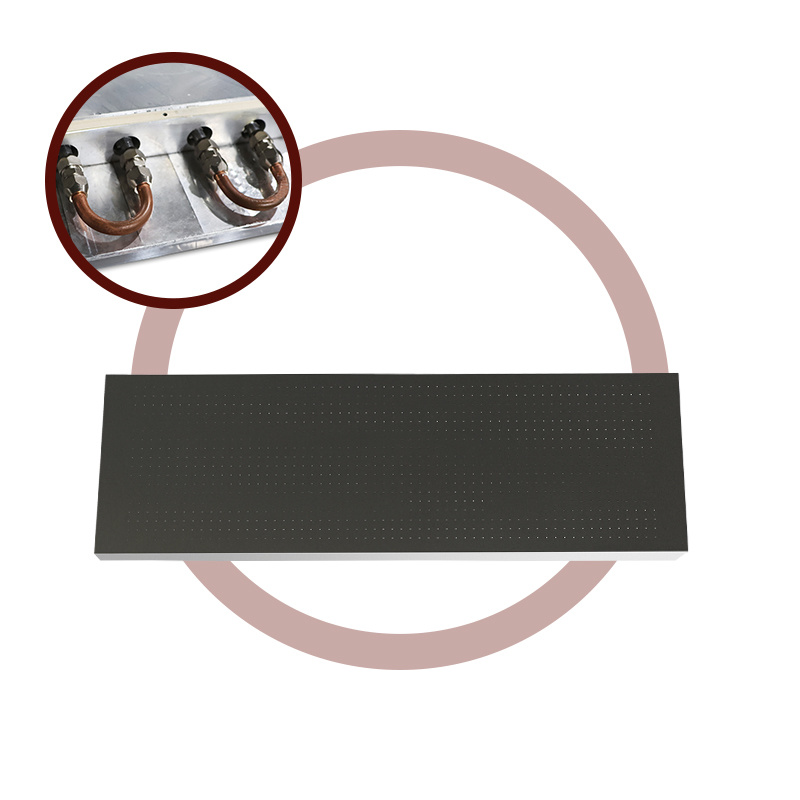

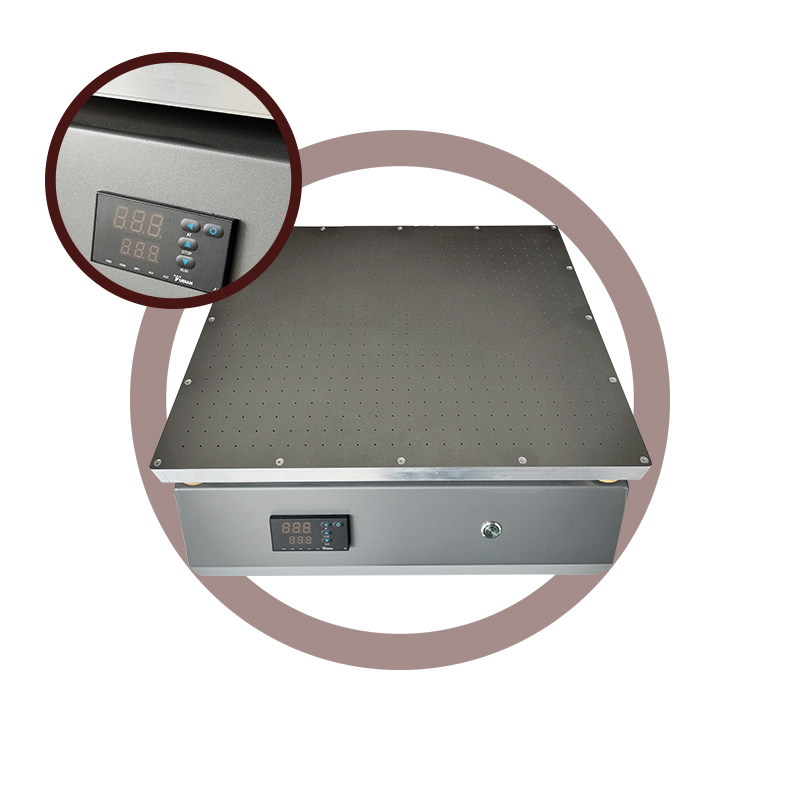

Yinmei Precision Vacuum Adsorption Platform can be customized according to customer requirements, whether it is platform specifications and dimensions, hole diameter and pitch, suction area, suction port diameter, number of suction ports, interface method, or any partitioning, individual suction or no suction, all can be customized.

key word:

Classification:

Product details

Specification Information

| Platform Specifications | Platform Thickness | Panel Aperture | Panel Pitch | Panel Material | Interface Type |

| Maximum Without Splicing | 25 | 1 | 15 | Alloy Aluminum | Flange |

| 4000*2100 | 35.5 | 1.5 | 20 | Stainless Steel | Threaded |

| 42.5 | 2 | ||||

| 53.5 | |||||

| Surface Treatment | Flatness | Panel Thickness | Base Plate Thickness | Suction Diameter | Partition |

| Hard Oxidation | ≤ 0.2mm | 2 | 2 | ɸ 50 | Customizable |

| Fluorocarbon Coating | 3 | ɸ 40 | |||

| Bright Aluminum | ɸ 30 | ||||

| Customizable | |||||

What problems can the Silver Beauty Vacuum Adsorption Platform solve for the printing industry:

1. Material Fixation and Flattening:

The vacuum adsorption platform can firmly adsorb various rigid and soft materials such as wood, metal, glass, plastic, paper, etc., ensuring they do not move or deform during the printing process.

Through evenly distributed vacuum suction, the platform keeps the material surface flat, which is crucial for achieving high-quality printing results.

2. Improve Printing Accuracy:

The fixed material surface allows the UV flatbed printer's print head to position more precisely and accurately spray ink onto designated locations.

A flat material surface reduces errors during printing, enhancing printing accuracy and detail expression.

3. Protect the Print Head:

The vacuum adsorption platform fixes the material, reducing friction between the material and the print head during printing, thereby extending the print head's lifespan.

It prevents issues such as print head damage or clogging caused by material movement.

4. Adapt to Complex Shapes:

For materials with complex shapes or edges, the vacuum adsorption platform can adaptively adsorb according to their shape, ensuring printing integrity and accuracy.

This enables UV flatbed printers to handle a wider variety of printing tasks, including three-dimensional objects or irregularly shaped items.

5. Improve Production Efficiency:

Stable suction force and material fixation reduce interruptions and errors during printing, thereby improving production efficiency.

Operators can focus more on setting up and monitoring printing tasks without worrying about material movement or deformation.

Related products