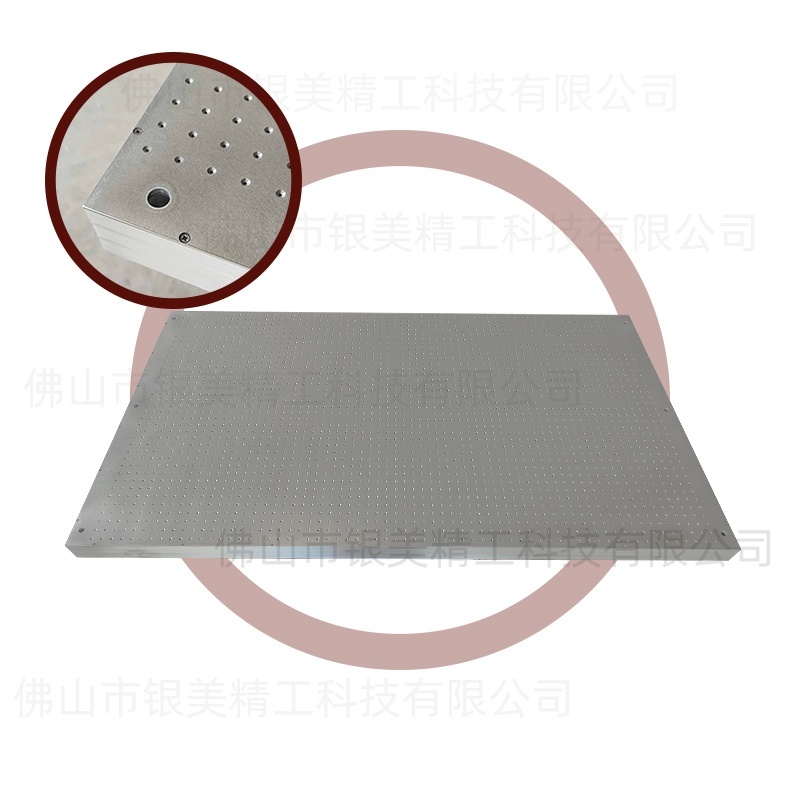

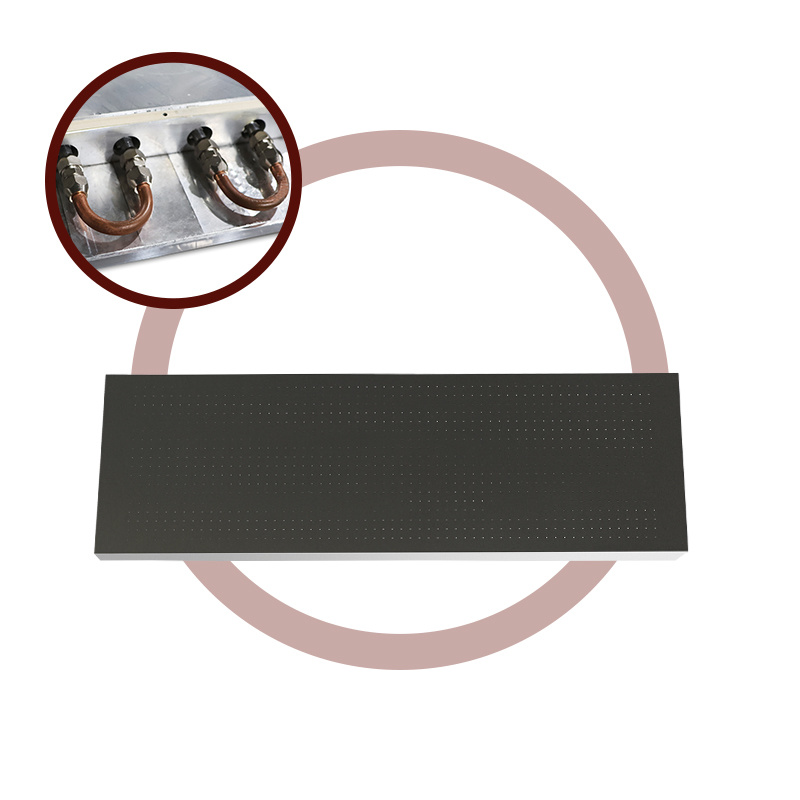

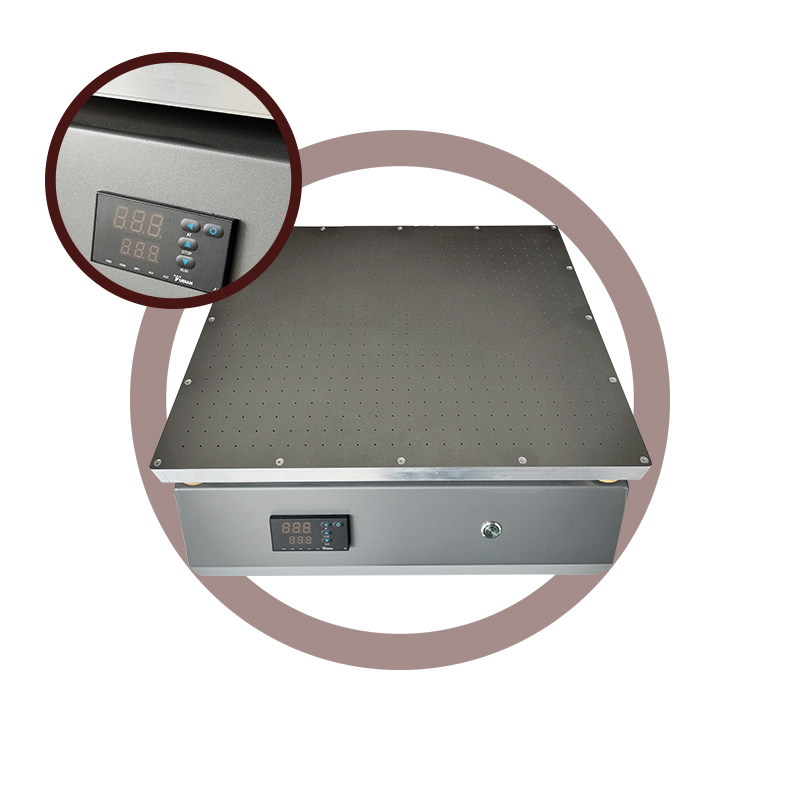

water cooling constant vacuum table

SilverMei water-cooled constant temperature vacuum adsorption platform, prevents deformation of flexible materials due to heat during printing

key word:

Custom

water-cooled constant temperature vacuum adsorption platform

Classification:

Product details

Platform Custom Specification Information

|

Platform Specifications |

Platform Thickness |

Panel Aperture |

Panel Pitch |

Panel Material |

Interface Type |

|

Maximum Non-Splicing |

25 |

1 |

15 |

Alloy Aluminum |

Flange |

|

4000*2100 |

35.5 |

1.5 |

20 |

Stainless Steel |

Threaded |

|

|

42.5 |

2 |

|

|

|

|

|

53.5 |

|

|

|

|

|

|

|||||

|

Surface Treatment |

Flatness |

Panel Thickness |

Base Plate Thickness |

Suction Port Diameter |

Partition |

|

Hard Anodizing |

≤0.2mm |

2 |

2 |

ɸ50 |

Customizable |

|

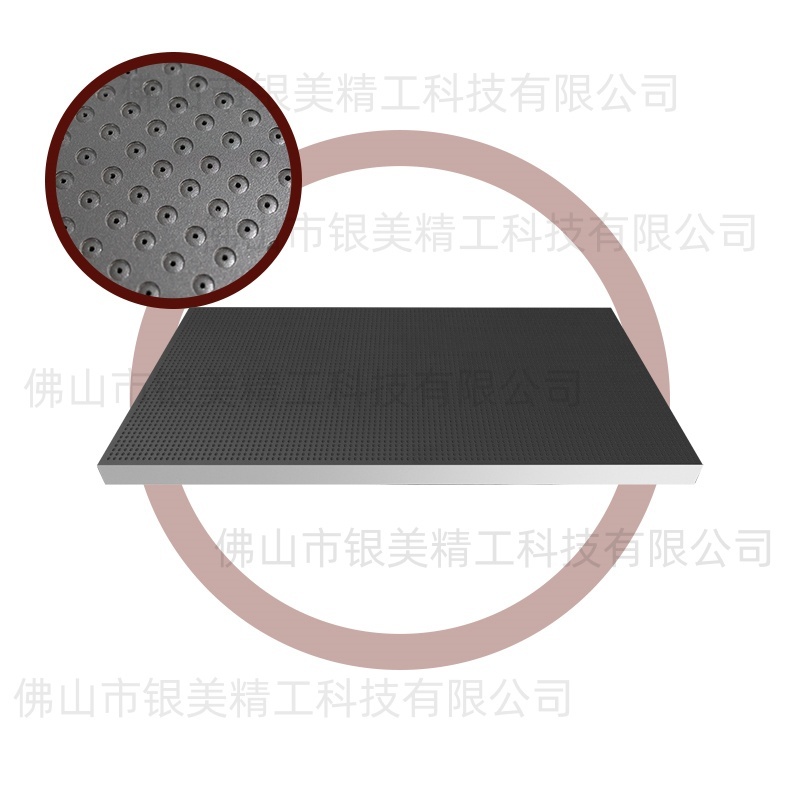

Fluorocarbon Coating |

|

|

3 |

ɸ 40 |

|

|

Bright Aluminum |

|

|

|

ɸ 30 |

|

|

|

|

|

|

Customizable |

|

Product Introduction:

[Yinmei Advantages ] Minimum Order Quantity of One Piece

Can be customized according to customer requirements Diameter and spacing of suction holes, suction port specifications and positions, suction area range and division, size, shape, surface treatment process, machining, etc.

[Yinmei Advantages ] Can be customized in various sizes

Yinmei can produce vacuum suction platforms up to 4000mm* 2100 mm (non-splicing) size

[Yinmei Advantages] High Flatness

Yinmei vacuum suction platforms have good flatness and deflection, generally controlled within 30 microns, with a minimum of 10 microns; deflection under 30 kg load is less than 10 microns.

[Yinmei Advantages ] Freely Customizable

Customizable sensing windows 、 Punching 、 Riveting and other processing. The vacuum suction platform can be fixed or installed on other equipment according to customer needs. 吸台固定或安装到其他设备上。

[Yinmei Advantages ] Lightweight & High Strength

Yinmei vacuum suction platforms use aluminum honeycomb structure inside, lightweight and strong, made entirely of aluminum alloy materials, with a density of about 25-35 kg per square meter, bearing 30 kg without deformation.

[Yinmei Advantages] Scratch and Wear Resistant

Yinmei vacuum suction platform surfaces have multiple treatment processes, including fluorocarbon PVDF powder coating, anodizing, and hard anodizing. Hard anodizing offers the best scratch and wear resistance, with surface hardness reaching HV500-700.

[Yinmei Advantages ] Yinmei Vacuum Suction Platforms Have Wide Applications

Vacuum suction platforms are used in UV flatbed printing, flexible material cutting, PCB drilling and inspection, vacuum lamination, screen printing, robotic 3D printing, and other industries requiring high-precision machining or milling of metal blocks or thin sheets.

FAQ & Basic Questions:

1. About Customization Services

Q1: What types of customization services does Foshan Yinmei Suction Platform Manufacturing Co., Ltd. offer?

A: We provide comprehensive vacuum suction platform customization services, including size customization, material selection, suction function configuration, etc.

Q2: How to start the customization process?

A: You can contact our sales through the backend, initially communicate your needs and budget. Then, our professional engineers will coordinate with you in detail for requirement confirmation and preliminary design. 工程师会与您详细对接,进行需求确认和初步方案设计。

2. Materials and Specifications

Q3: What materials are available for custom suction platforms?

A: Yinmei mainly offers aluminum alloy and stainless steel materials.

Q4: Are there size limitations for custom suction platforms?

A: Yinmei customization service advantages lie in flexibility, we can produce up to 4000 mm*2100 mm size suction platforms (larger sizes can be spliced) . Specific sizes depend on your actual usage requirements. 情况来确定。

3. Design and Function

Q5: Is it possible to provide a preview of the design draft?

A: Of course, after the design plan is finalized, we will provide detailed design drafts for your preview.

4. Production and Delivery

Q6 : What is the production cycle for customized products?

A: The production cycle depends on the product processing complexity and current factory order volume, usually completed within 25-30 days after confirming the design plan and paying the deposit. We will maintain close communication with you to ensure production progress.

Q7 : How is product transportation and installation arranged?

A: We provide nationwide transportation services and can arrange a professional installation team for on-site installation and debugging according to customer needs, ensuring the product is put into use smoothly.

5. After-sales Service

Q8 : What after-sales services are available for customized products?

A: We provide a one-year warranty service for all customized products.

Related products