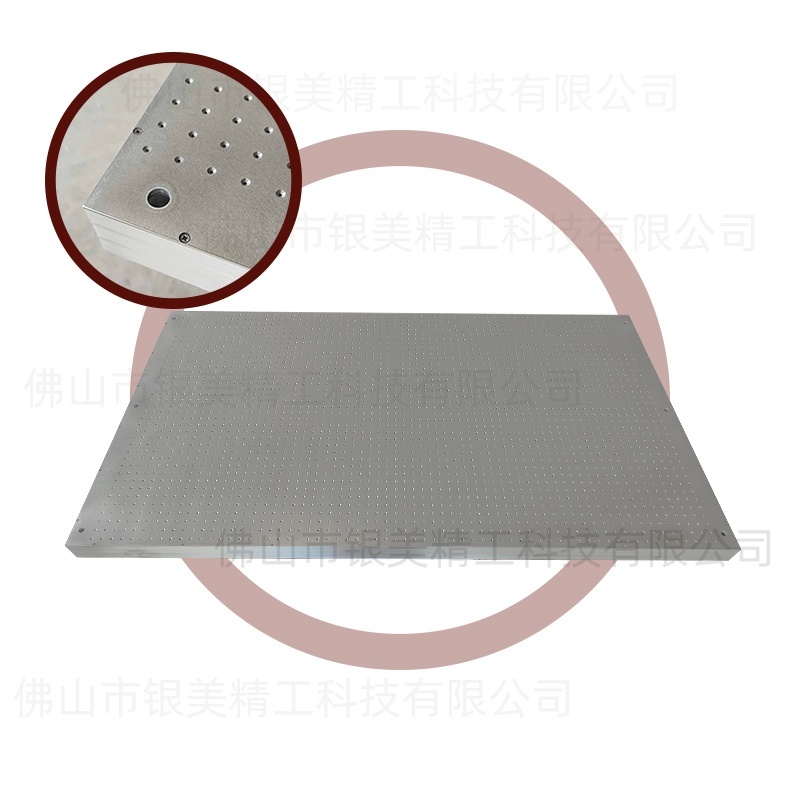

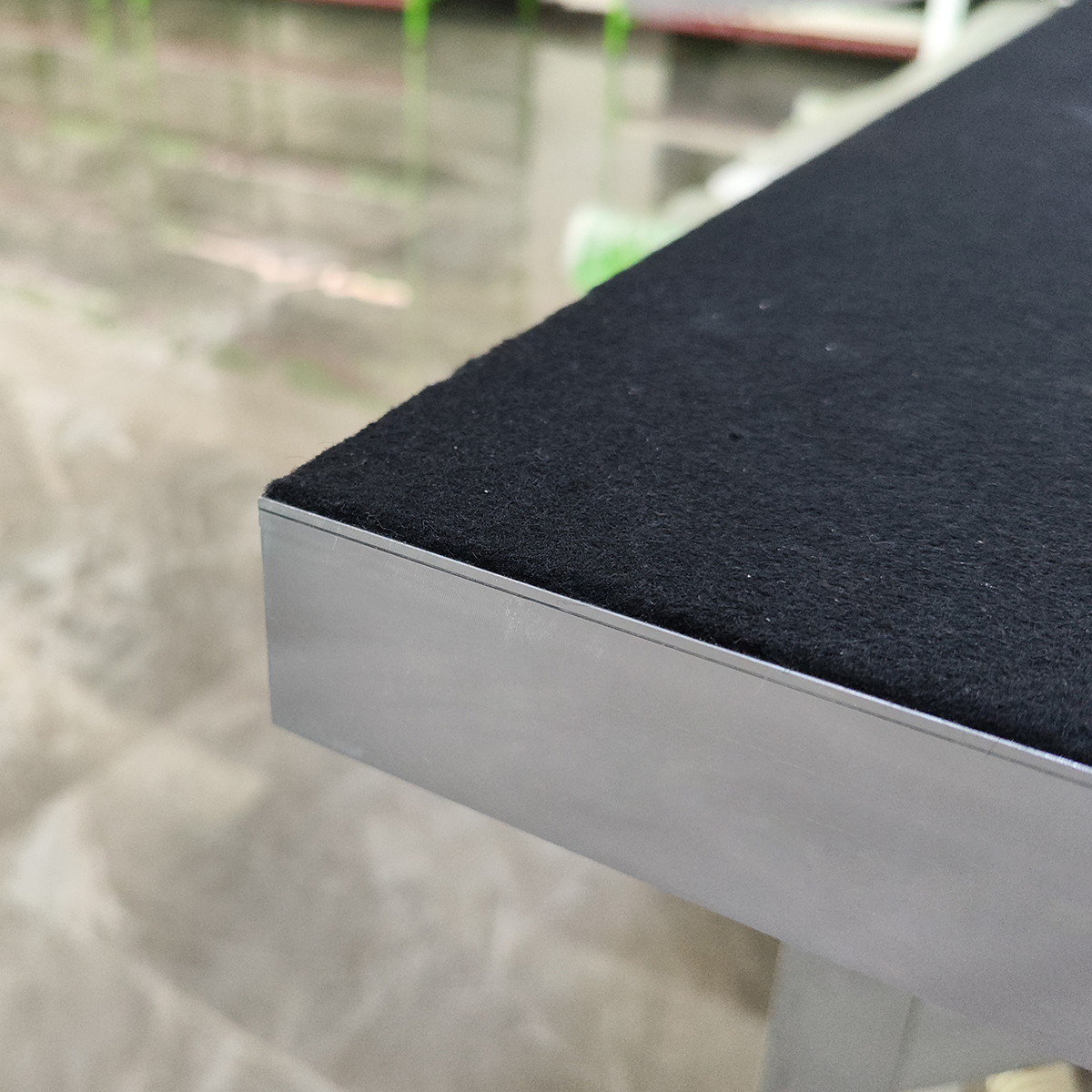

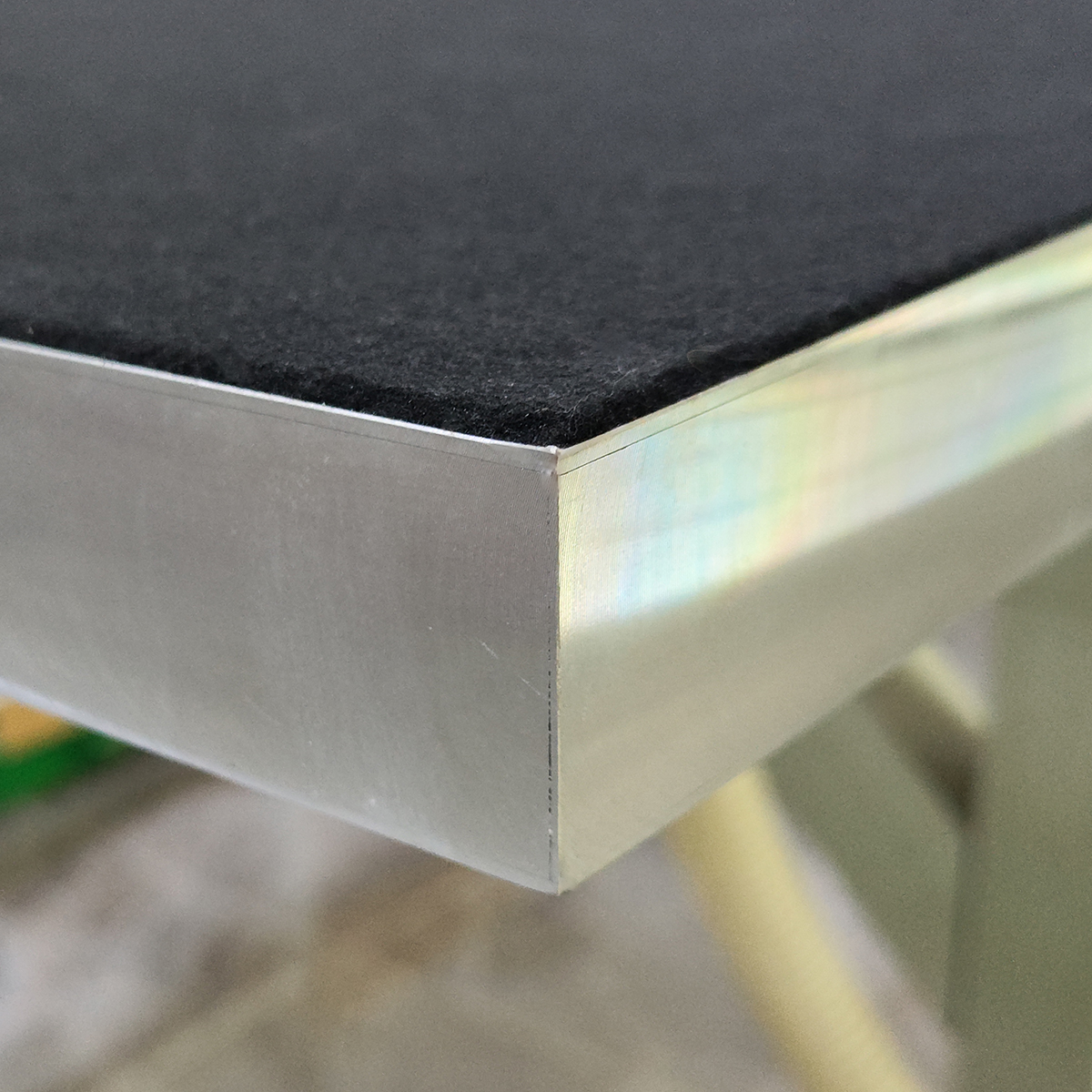

Felt Suction and Floating Integrated Table

No air float table with floating beads, integrated suction and floating platform. Compared to the ball-type integrated suction and floating platform, this felt applies less pressure on the workpiece and is less likely to scratch it.

key word:

Classification:

Product details

Technical Parameters And Characteristics

|

SPEC |

THICKNESS |

PANEL HOLE DIAMETER |

PANEL HOLE SPACING |

PANEL MATERIAL |

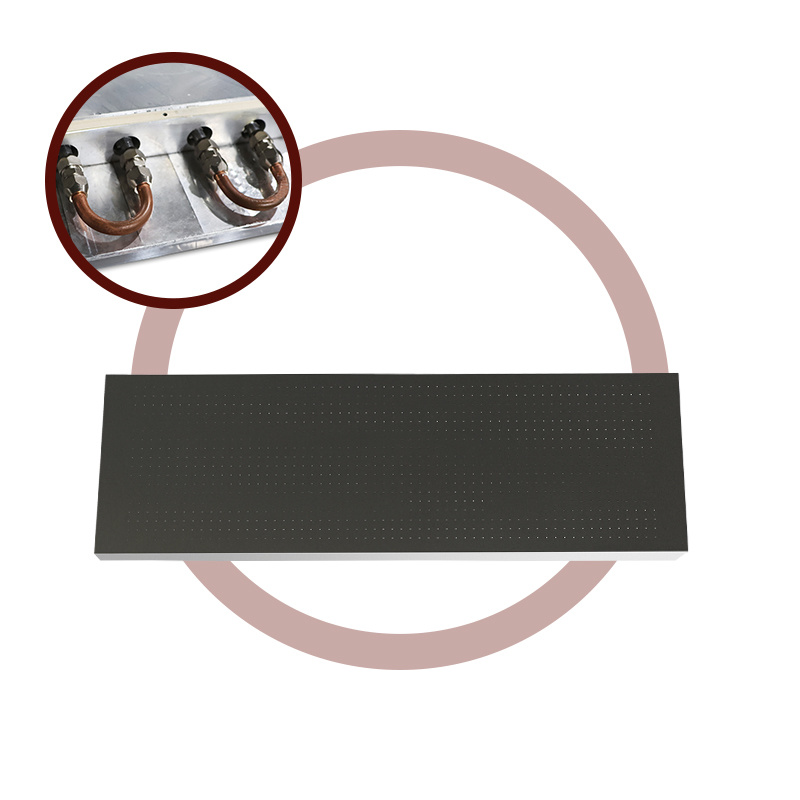

INTERFACE MODE |

|

2500*1300*42.5 |

42.5 |

0.8 |

20 |

Aluminum alloy |

flange |

|

SURFACE FINISHING |

FLATNESS (MM) |

PANEL THICKNESS |

BACK THICKNESS |

PUMPING APERTURE |

|

|

Hard oxidation |

≦0.10 |

2.0 |

2.0 |

Φ50 |

|

Above Technical Specifications Can Be Customized Basing On The Following Date

|

SPEC |

THICKNESS |

PANEL HOLE DIAMETER |

PANEL HOLE SPACING |

PARTITION |

INTERFACE MODE |

|

Customized |

25 |

0.8 |

10 |

|

flange |

|

|

35.5 |

1.0 |

20 |

Customized |

Screw |

|

|

42.5 |

1.5 |

30 |

|

|

|

MAX:4000*2100 |

53.5 |

Customized |

|

|

|

|

|

75 |

|

|

|

|

|

SURFACE FINISHING |

FLATNESS (MM) |

PANEL THICKNESS |

BACK THICKNESS |

PUMPING APERTURE |

|

|

Hard oxidation |

≦0.10 |

2.0 |

2.0 |

Φ40 |

|

|

Aluminium primary |

|

|

3.0 |

Φ50 |

|

|

PVDF |

|

|

2.0 |

Customized |

|

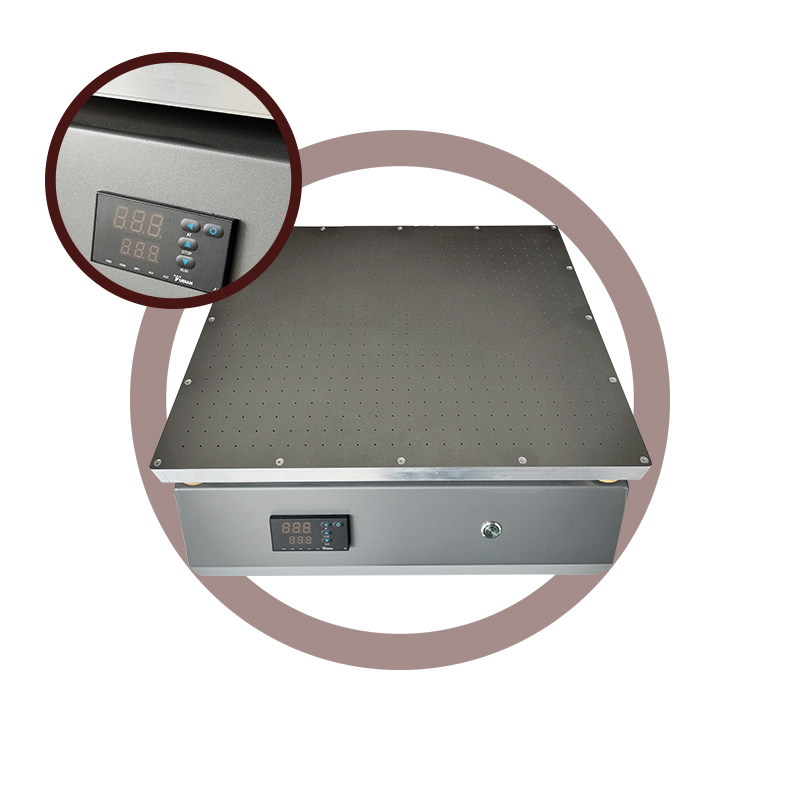

Yimiwell has over 10 years of experience in the vacuum table manufacturing field.

Our goal remains consistent: to produce vacuum tables that satisfy customers.

The surface is treated with hard anodization, achieving scratch resistance and wear resistance.

The lightweight sandwich design enables an excellent strength-to-weight ratio.

The honeycomb core provides uniform air flow, thereby minimizing resistance.

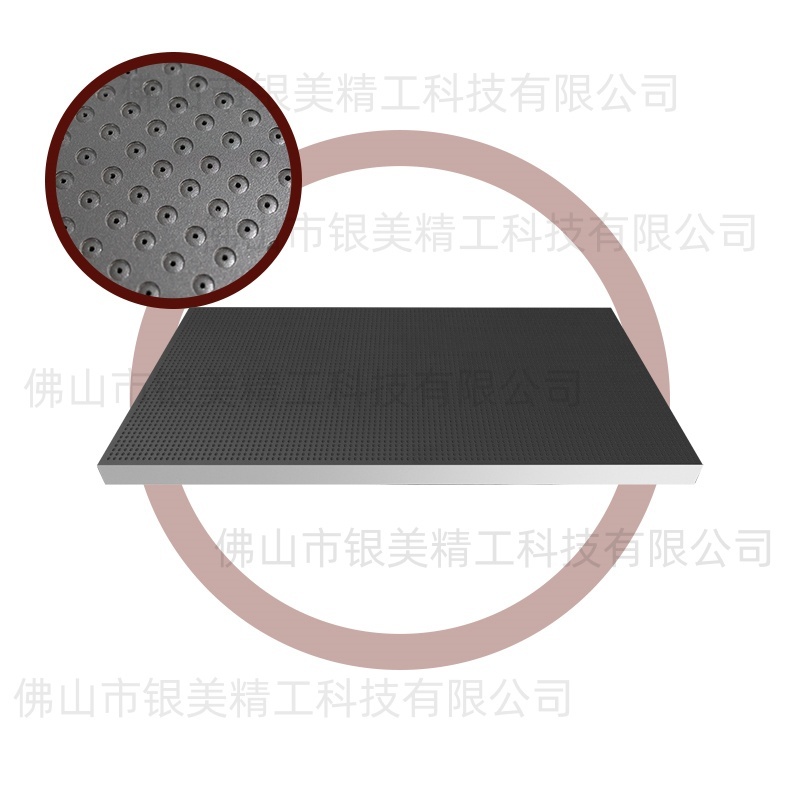

Felt-Type Air Floating Table

Designed for high-precision processing applications, it minimizes the risk of surface damage by replacing traditional air float nozzles with a felt-covered surface. It’s especially suitable for handling sensitive materials such as display glass, where standard air-floating tables may pose a risk of scratching or abrasion.

Felt Suction and Floating Integrated Table

CharacteristicsOfYIMIWELLVacuumTable:

Yimiwell Vacuum Table are made of aluminum alloy in honeycomb structure,

with extremely high flatness of surface. in addition to the advantages of light weight,

high strength, high rigidity, bending resistance and deflection resistance, this

platform also has the advantages of high flatness, small deflection value, large

adsorption force, scratch resistance and wearresistance.

THE DETAILED ADVANTAGES ARE AS FOLLOWS:

1.LARGE SURFACE WITH HIGH FLATNESS

The maximum length and width dimensions of the Yimiwellvacuumtable panel can

reach 4000×2100mm (splicing is available for sizes exceeding this range). It boasts

excellent flatness and deflection performance:

Flatness: Generally controlled within 0.20mm, with the minimum down to 5μm.

Deflection: Less than 0.10mm under a load of 30 kg.

2.LIGHT WEIGHT AND LARGE BEARING CAPACITY

Yimiwellvacuumtable uses aviation-grade aluminum honeycomb structure with all

aluminum alloy integrated molding. Lightweight design ensures >60kg/m² single

point load-bearing without deformation, combining high strength and stability.

3.GREATSUCTIONINWELL-DISTRIBUTED

Yimiwell vacuumtable ensurestheperformanceoftheplatformarenotaffected

andalsomakesthesuctionforcegreatinwell-distributedatanyposition.

4.ANTI-SCRATCHANDWEAR-RESISTANT

The surface of Yimiwell vacuum table can undergo natural anodizing and hard

anodizingtreatments. Among them, hard anodizing providesthe best scratch

andwearresistance,withamaximumsurfacehardnessofuptoHv500.

5.YIMIWELL VACUUM TABLECAN BECUSTOMIZEDBASING

ONCUSTOMER'SDEMAND.

Prev

Next

Prev

Next

Related products