CNC Cutting Machine Aluminum Chuck Vacuum Suction Table

CNC Cutting Machine Aluminum Chuck Vacuum Suction Table ,cnc cutting machine,tables cnc vacuum,chuck vacuum, Spec(mm) Thickness(mm) Panelaperture(mm) Panel hole spacing(mm) Panel material Interface method MAX: 25 1 15 Aluminium alloy flange 4000*2100 35.5 1.5 20 stainless steel screw 42.5 2 53.5 Surface Treatment Flatness Panel Thickness Back Thickness Pumping Aperture Partition Hard oxidation ≤0.2mm 2 2 ɸ50 Customizable PVDF 3 ɸ 40 Aluminum primary ɸ 30 Customizable CHARACTERISTICS OF YINMEI VACUUM PLATFORM 【 Silver Beauty Advantage 】 One piece minimum order We can customize the diameter and spacing of adsorption holes, specifications and positions of suction ports, range and differentiation of adsorption areas, size, shape, surface treatment process, processing, etc. according to customer needs. 【 Advantages of Yinmei 】 Customizable in various sizes Yinmei can produce vacuum tables with dimensions of 4000mm * 2100mm (without splicing) 【 Advantages of Yinmei 】 High flatness The Yinmei vacuum table has good flatness and deflection, with flatness generally controlled within 30 threads and a minimum of 10 threads; The deflection value is less than 10 threads under a force of 30 kilograms. 【 Advantages of Yinmei 】 Free customization Customization of sensing windows, punching, riveting and other processing can be freely carried out. The vacuum suction table can be fixed or installed on other equipment according to the customer's situation. 【 Advantages of Yinmei 】 Lightweight&High Strength The interior of the Yinmei vacuum table adopts an aluminum honeycomb structure, which is lightweight and has strong load-bearing capacity. All aluminum alloy materials are used, with a density of about 25-35 kilograms per square meter and a load-bearing capacity of 30 kilograms without deformation. 【 Advantages of Yinmei 】 Scratch resistant and wear-resistant There are various treatment processes for the surface of the Yinmei vacuum table, including fluorocarbon PVDF powder coating, anodizing, and hard oxidation. The hard oxidation process is selected according to actual needs, among which the hard oxidation process is the most scratch resistant and wear-resistant, and its surface hardness can reach HV500-700. 【 Advantages of Yinmei 】 Yinmei vacuum table is widely used Vacuum suction tables are applied in industries such as UV flatbed printing, flexible material cutting, PCB drilling and testing, vacuum bonding, screen printing, robot 3D printing, etc., for high-precision machining or precision milling of metal blocks or sheets.

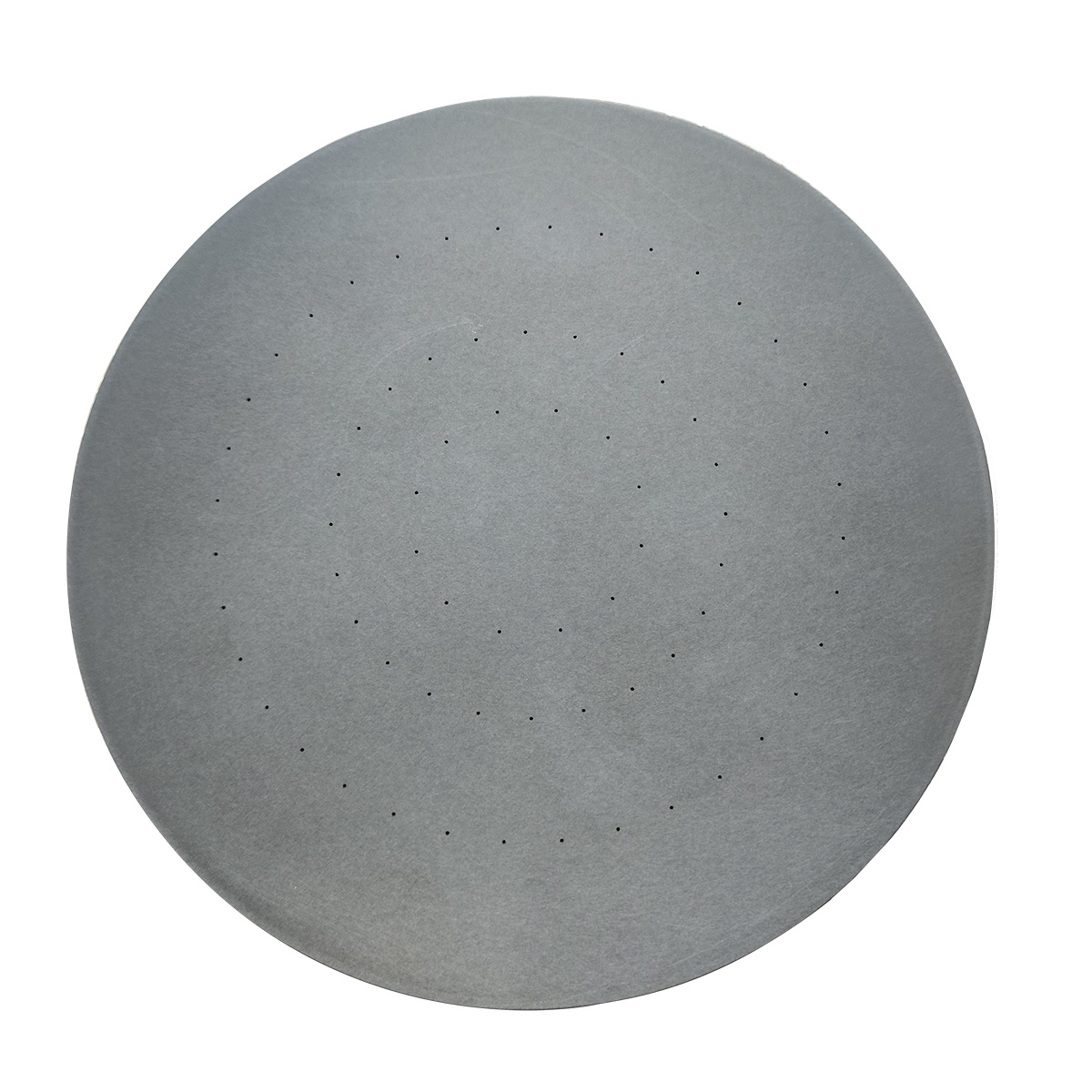

Yinmei can customize various shapes of suction tables,Circular Vacuum Table Chuck

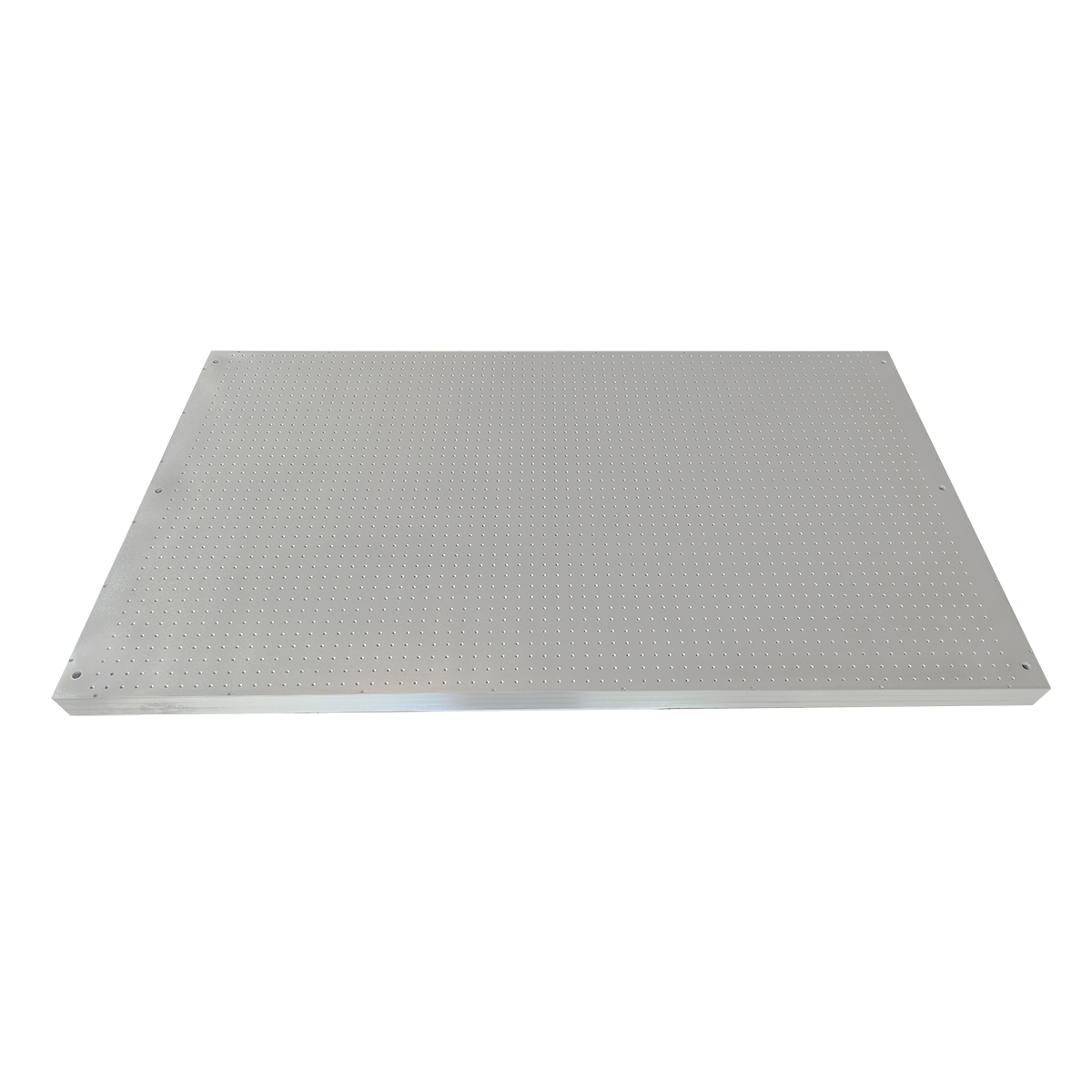

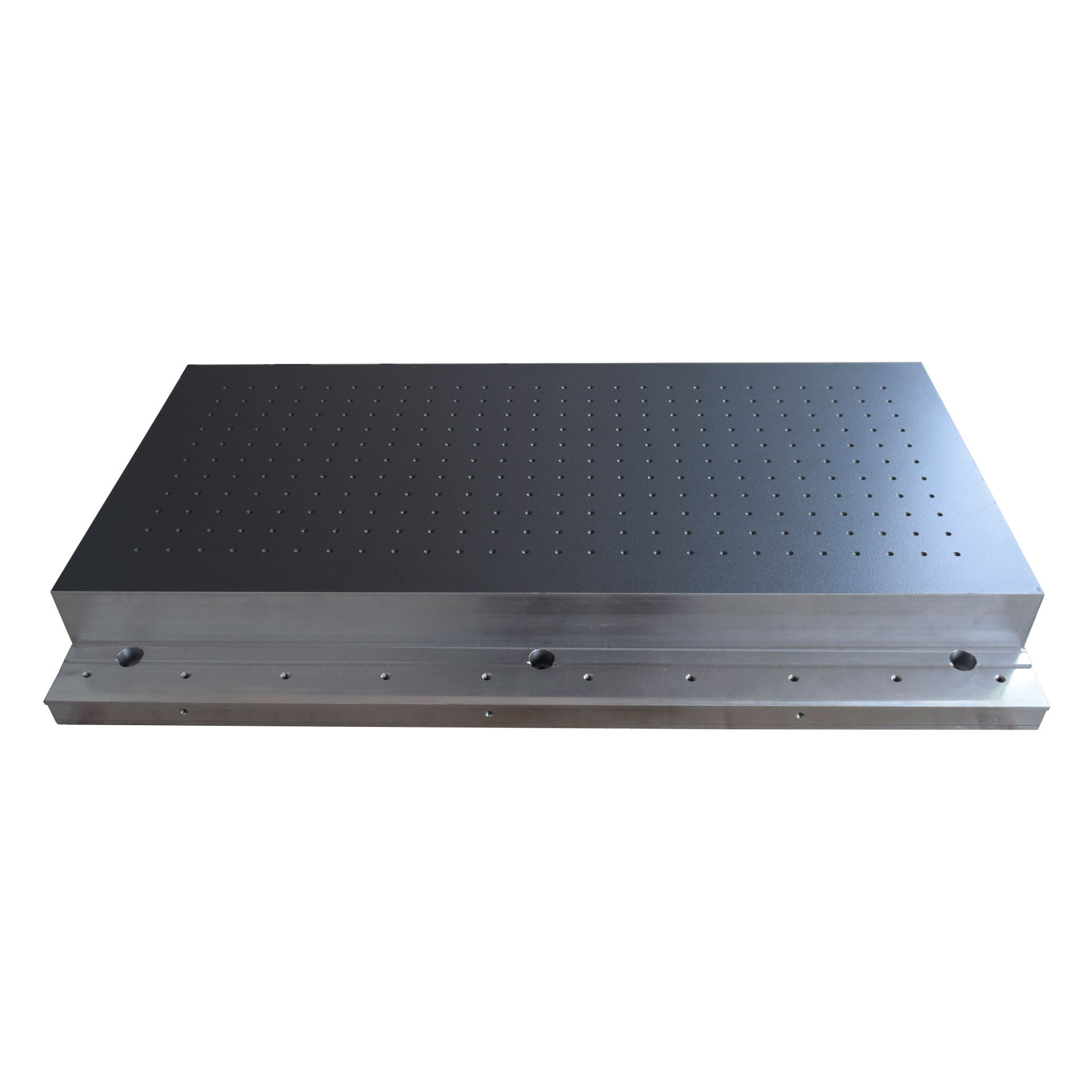

Stainless steel cutting machine vacuum honeycomb table

1. Ultra high precision plane, with large and uniform adsorption force. 2. Stainless steel panel material, high hardness, scratch resistance and wear resistance. 3. The internal honeycomb structure has high structural strength and stability.

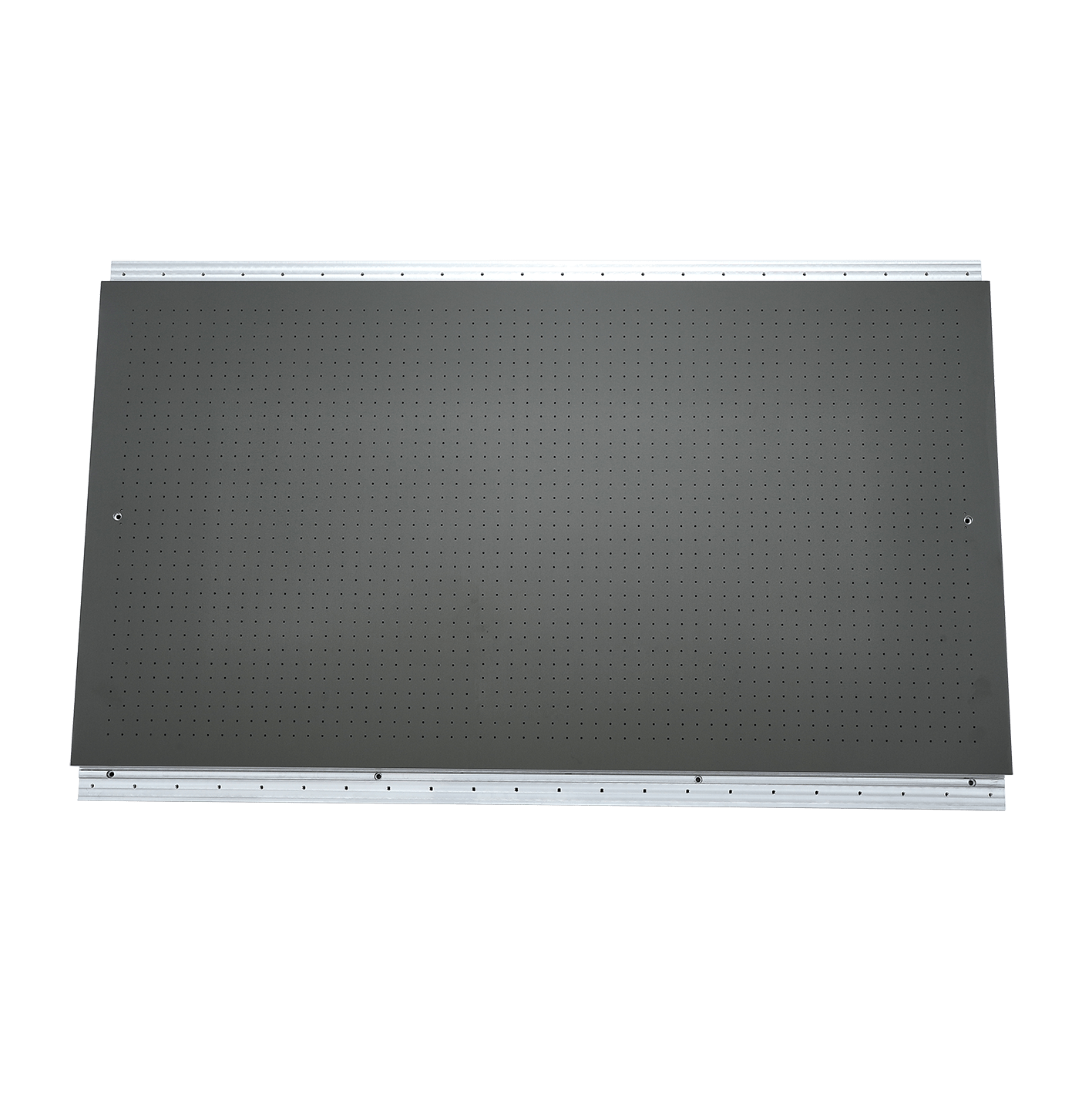

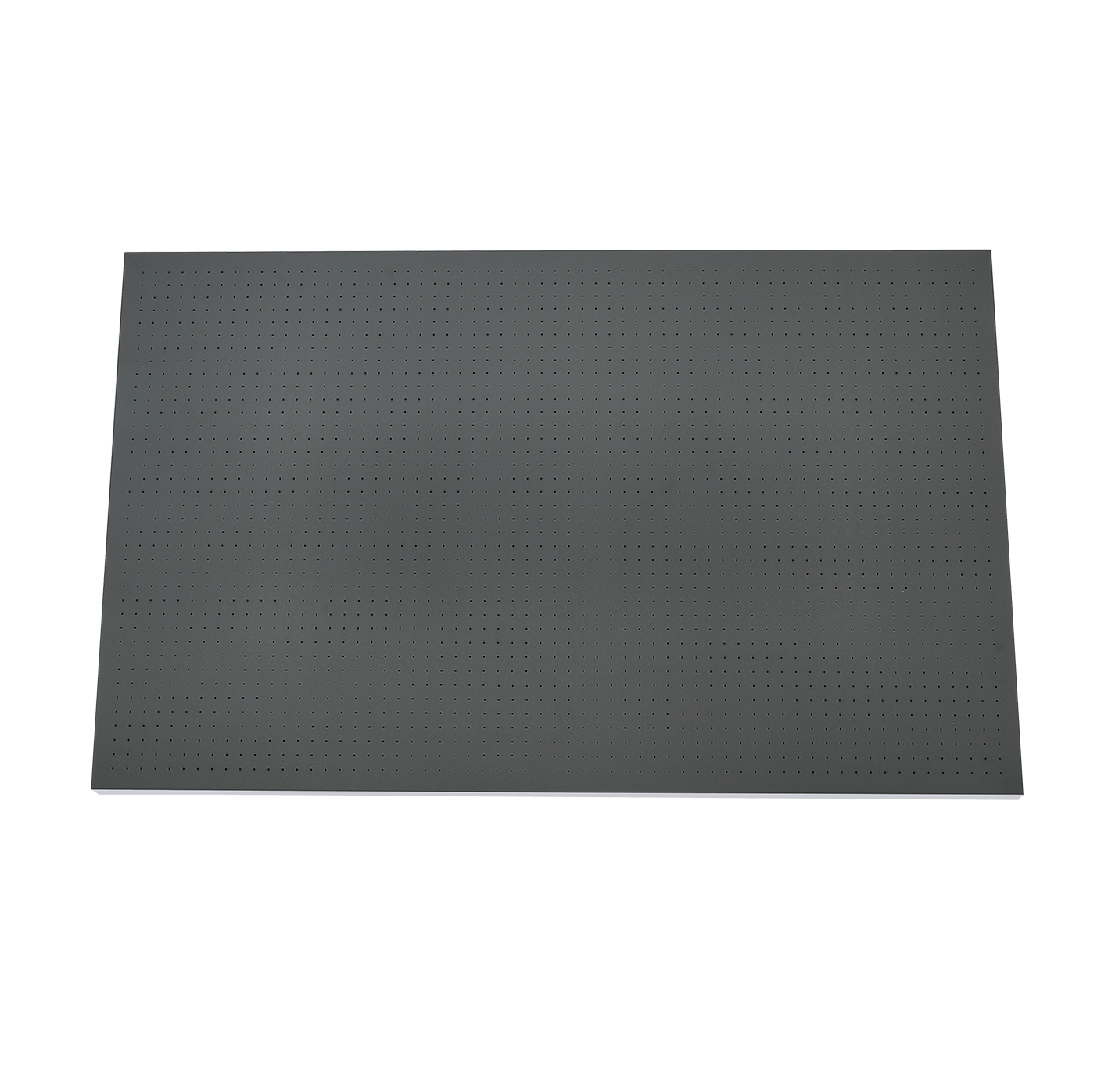

Cutting machine vacuum table chuck

Yinmei Vacuum adsorption platform YM-1300*1000*42.5 Cutting machine adsorption platform (cone hole 1*3, hard oxidation)

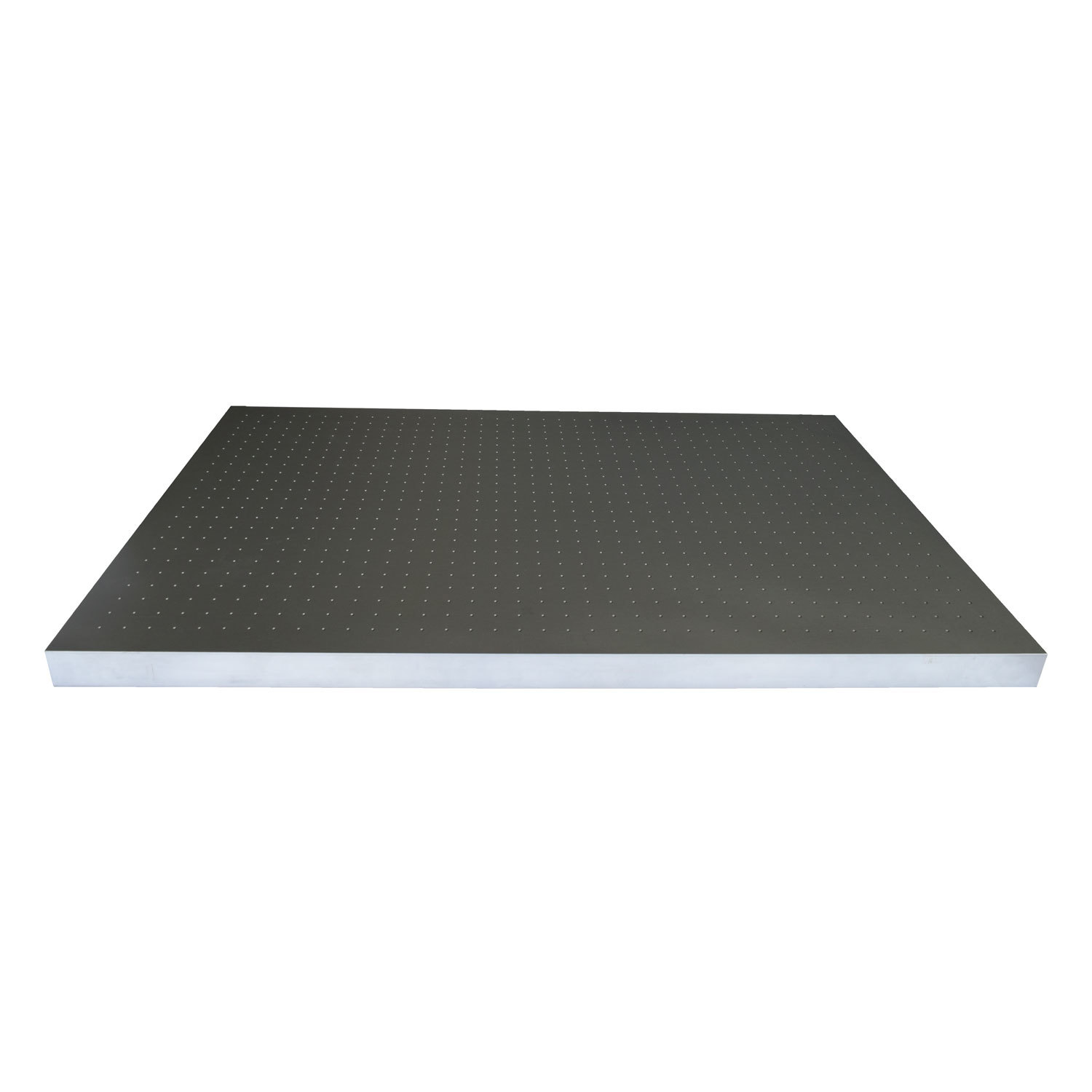

Cutting machine vacuum suction platform/Yinmei vacuum adsorption platform

Vacuum platform for digital cutting machine

Digital cutting platform on the back of the guide rail

Digital cutting platform (front rail)

Digital cutting platform, front mounted guide rail

Cutting machine vacuum suction platform/cutting platform back guide rail

Vacuum adsorption platform for cutting machine